Schmidt |Jet sweeper|TJS / TJS-C

Highly efficient clearing process

The TJS jet sweeper combines three steps into one single operation and brings your runway quickly back to blacktop. Whereas the snow plough clears the majority of the snow to the side, the brush clears the remaining snow and slush while the blower unit generates a powerful air flow across the entire sweeping width to remove any remaining moisture. Here you are with more details of the three units:

Snow plough

Clean and aggressive clearance is achieved with the Schmidt MS Tarron airport snow ploughs, such as the MS 56.2 NA. These are designed for fast snow clearance at airports and offer outstanding performance with optional fine clearing bar, ejection stop or low blade shape.

Sweeping unit

The hydraulically-driven brush is mounted to a supporting frame and suspended via a parallelogram lifting system, so that it rests on the surface regardless of vehicle movement and uneven ground. The brush’s automatic and stepless sweeping pattern adjustment is carried out hydraulically and determined by the height adjustment of twin castors. During operation, the brush speed is adjusted automatically to suit the driving speed and shown on the control panel’s display. A long brush service life is possible – thanks to the wear-dependent brush speed adjustment.

The twin castors offer very quiet, vibration-free and smooth sweeping performance, while level snow ejection and the cleanest fine clearing ensure maximum safety. This is achieved thanks to aerodynamic spoiler guidance, automatic spoiler adjustment and wear-dependent brush speed adjustment. This permits the jet sweeper to deliver a specific fine clearing result, while the robust design offers both optimum operational capability and maximum safety.

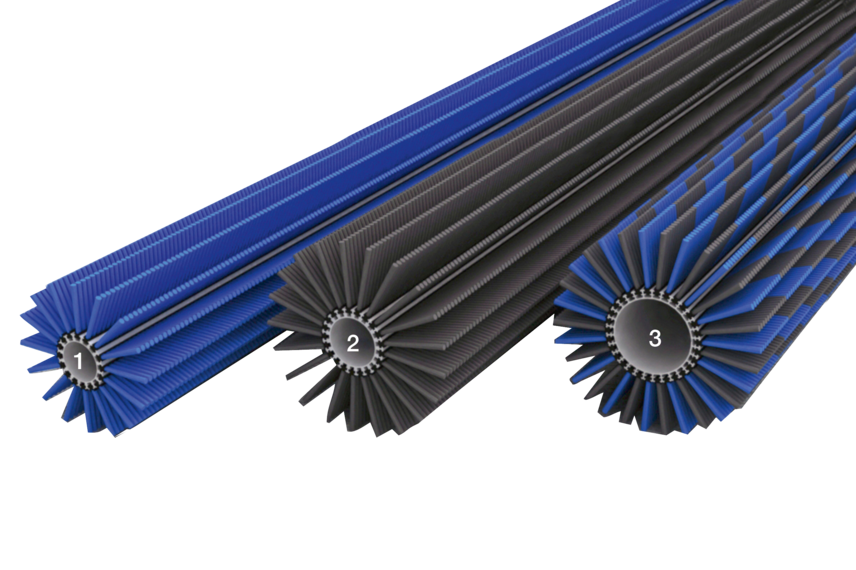

Optimum brush life

Optimum brush life is achieved with a 21-piece cassette brush set with the longest bristle length. This type of brush is the most economical based on the number of cassettes to brush cost ratio – a recommendation we are happy to share with you. Depending on your requirements, you can choose between plastic (polyurethane) bristle materials [1], steel [2] or mixed (polyurethane/steel) [3].

Blower unit

The blower unit of the TJS/TJS-C is located directly behind the sweeping unit. The blower removes any remaining water and slush from the clearing area, ensuring optimum friction values and better braking action on runways. The blower is driven hydraulically by the auxiliary engine via a variable displacement pump. Since the air flow is emitted directly above the ground, there is hardly any performance loss. In addition, the blower speed can be regulated in two stages. The aerodynamic air flow in the air duct ensures optimum blowing air performance over the entire clearing area. A constant air speed ensures uniform clearing of the snow-covered area.

Drive

The drive motor drives the hydraulic pumps for operating and controlling the sweeping unit and blowing unit. The snow plough is controlled by a hydraulic system driven by the carrier vehicle's engine. The TJS/TJS-C's hydropneumatic chassis offers the operator additional comfort in the field.

The TJS-C’s environmentally-friendly drive technology

The importance of environmental and climate protection also presents airports with growing challenges. In order to achieve the balance between the required performance of a snow clearing machine and environmentally responsible fuel consumption, we use Volvo's CO2-neutral dual-fuel engines, which run on a mixture of biogas and biodiesel. Depending on the required power, 60 to 80% of the biodiesel can be substituted with biogas. As a result, the engines make an important contribution to the positive environmental balance of any airport. As an alternative fuel variant, HVO (Hydrated Vegetable Oil) can also be used.

Motion control

Both pulse control and synchronous control are possible for the snow plough, sweeping unit and blower, i.e. all components can be controlled individually or synchronously. On the one hand, this makes the clearing process particularly efficient (synchronous control), while on the other hand, pulse control (manual) can be used to react to special situations (e.g. readjustment of the snow plough).

Operating concept

State-of-the-art control technology is an important step in the safe and efficient clearing of airport tarmac. Logical and intuitive menu navigation and automatically controlled processes help to support drivers by ensuring that concentration remains focused on the clearing operation. The display indicates the operating hours data when the machine is at a standstill; information about the engine speed, brush speed and blower output can be called up when the engine is running. The display also provides a comprehensive overview of fault or error messages.

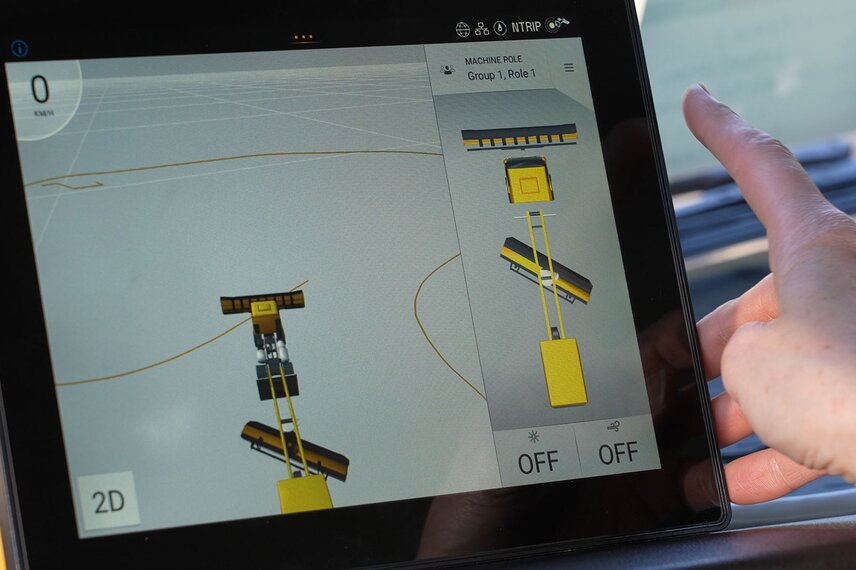

AirfieldPilot

The high-precision AirfieldPilot driver assistance system, which takes into account the individual characteristics of an airport and has been successfully tested in practice, makes it possible to significantly increase the performance of a clearing fleet. Furthermore it saves costs, allows you to plan more flexibly and leads to greater safety during operations - especially for your staff. In addition, the system reduces operational risks and the probability of occurrence of damage. Another equally important factor is the ecological aspect. By optimising fuel consumption, it contributes to more environmentally friendly operation. The AirfieldPilot can be used for various automated or autonomous deployment concepts:

- As a classic driver assistance system with navigation, route guidance, equipment guidance and communication between vehicles (V2V)

- For supervised automated operations, in which the carrier vehicle and the jet sweeper are controlled automatically, taking into account the topographical and geographical features, but a driver in the cab remains responsible for the operation and can intervene at any time

- For fully automated operations, including the increased safety requirements for such concepts

Difference between TJS and TJS-C

The TJS includes an all-wheel-drive towing vehicle with front-mounted snow plough and a jet sweeper with integrated coupling system – either as a semi-trailer or as a trailer. The auxiliary engine, which drives both the sweeping unit and the blower unit hydraulically, is located in the rear engine compartment. On the other hand the compact TJS-C has a powerful tractor unit, including a snow plough, plus the same options for the brush roller and blower unit as the TJS. The compact attachment to the tractor unit makes the TJS-C a compact and particularly manoeuvrable machine.

Towing vehicles and connections

With different coupling systems, we offer a wide selection of jet sweepers that are perfectly tailored to your individual requirements. By using a modular system that includes various TJS versions, working widths and clearing capacities, a customised TJS/TJS-C can be configured to meet your exact requirements. Within the coupling systems, we distinguish between three different variants:

Semi-trailers (A): For the semi-trailer version, all commercially available truck chassis can be used as a towing vehicle, including MAN, Mercedes-Benz, Volvo or other vehicles with fifth wheel coupling, ideally a 4x4 chassis.

4-wheel TJS with towbar (B): All commercially available chassis or tractors, ideally a 4x4 chassis, can be used for the 4-wheel TJS with towbar.

TJS-C: tractor unit (C): For the tractor unit version, we offer a Volvo with articulated steering or a Mercedes. This makes the TJS-C both compact and manoeuvrable.

Smart Service Concept

The Smart Service Concept equals easier maintenance. It allows free access to all important components and low service time due to the ease of access to the components. In addition, the TJS / TJS-C has a practical mounting bracket for the control panel on the control cabinet for service and workshop use. The optimised wiring harness layout ensures high quality standards and reduced service requirements. At the same time, the air intake underneath the bonnet ensures less air filter contamination.

Multitude of variants

The modular concept allows the TJS/TJS-C to be customised to suit your individual requirements and to fit any towing or carrier vehicle. Based on the basic variants 420, 560 and 630, which are determined by the brush width, the following options are available to you:

- Parking position for both the brush and the sweeping unit

- Different brush fill materials

- Additional blower unit in front of the brush

- Combination with airport snow plough from the Tarron-MS series with plough widths between 5,600 mm and 8,000 mm

- Additional rear axle steering for maximum manoeuvrability

- Traction weights for towing vehicle

- Engine: Hood can be tilted backwards; electro-hydraulic, manually operated unit for opening the engine hood; upward exhaust orientation possible

- Safety: Additional lighting; rear area monitoring; 270°/360° camera