In August 2025, Aebi Schmidt Group, NA hosted a comprehensive HV training program at its headquarters in Chilton, WI, in partnership with DEKRA Training Courses. Over three days, dealers, service personnel, and operators gained the skills to work safely and confidently with high-voltage systems, ensuring electric fleets operate reliably all season long.

Why High Voltage Training Matters

Electric sweepers aren’t just diesel machines with batteries swapped in—they are complex systems with unique maintenance needs. Without proper training, even routine service calls can become complicated. HV training ensures technicians understand the systems and know how to work safely and effectively, protecting both people and equipment.

Key benefits of HV training include:

- Safety & Confidence – Proper use of PPE, tools, and isolation techniques minimizes risk.

- Qualified Personnel – Expands the pool of staff certified to handle high-voltage systems.

- Fleet Reliability – Correct maintenance and troubleshooting prevent costly downtime.

- Regulatory Compliance – Keeps operations in line with high-voltage safety standards.

As one participant put it, «The training gave us confidence. We now know exactly how to work safely with these machines and keep them running at peak performance.»

Hands-On Experience Builds Skill

The program’s four core objectives:

- Safety First – Recognize hazards and apply proper PPE.

- System Knowledge – Understand how batteries, inverters, motors, and cooling systems interact.

- Emergency Response – Learn to respond effectively to incidents like thermal runaway.

- Preventive Care – Identify maintenance needs to reduce downtime and extend equipment life.

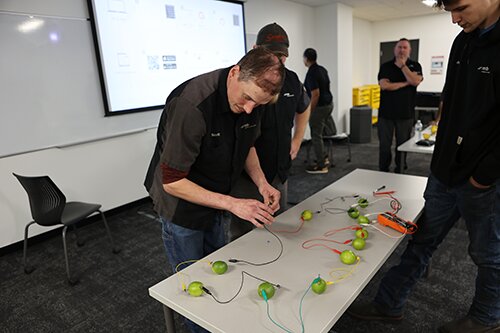

Practical, hands-on exercises—from circuit demonstrations to live shutdown procedures—helped participants internalize the material. This combination of knowledge and experience equips technicians to handle electric sweepers safely and efficiently in real-world operations.

The Customer Advantage

For organizations transitioning to electric fleets, HV-trained technicians deliver tangible benefits:

- Safer Crews & Equipment – Reduced accidents and equipment damage.

- Faster Repairs & Less Downtime – More trained personnel means quicker response times.

- Lower Costs – Preventive care reduces expensive failures.

- Greater Reliability – Teams keep sweepers operating at peak performance.

- Confidence in Transition – Customers trust electric fleets to deliver consistent service.

Ongoing Commitment

High Voltage Training is not a one-time event. It is part of Aebi Schmidt Group’s long-term commitment to customer success. Future programs will expand HV and e-mobility training opportunities with advanced certifications, flexible formats, and updated content to keep pace with evolving technology.