Turning Knowledge into Innovation

For our interns, the summer isn’t just about gaining experience, it’s about applying their education to solve real challenges for Swenson’s customers.

Aiden, a senior mechanical engineering student, shares, “The thing I’ve enjoyed most is being able to finally put together everything I’ve been learning in my classes and using the skills I’ve built over the years.” His work has helped streamline design processes and support interdepartmental collaboration - helping get quality equipment out the door faster and more efficiently.

Joseph, a rising senior majoring in mechatronics engineering, agrees that the experience has brought the classroom to life. “This internship has helped me develop my modeling, design, and communication skills. It’s taught me a lot about how the engineering process works in the real world—something you don’t always see in school,” he said. His contributions have strengthened internal collaboration, a key factor in ensuring Swenson continues to deliver reliable, high-performance equipment that meets customer needs across a range of applications.

Building More Than Just Equipment

A strong culture can make all the difference—for interns and customers alike. “The best part of interning at Swenson has been getting to know all the people here,” Joseph shared. “Everyone is incredibly friendly and supportive.” Aiden echoed that sentiment, noting, “I didn’t know what to expect at first, but everyone has been very welcoming. I’ve felt like part of the team from day one.”

That teamwork isn't just good for the interns—it creates a ripple effect that benefits the end user. When departments collaborate effectively and engineers can ask questions freely, it results in better, smarter designs that enhance the reliability of Swenson equipment in the field.

From Intern to Engineer: A Real Career Path

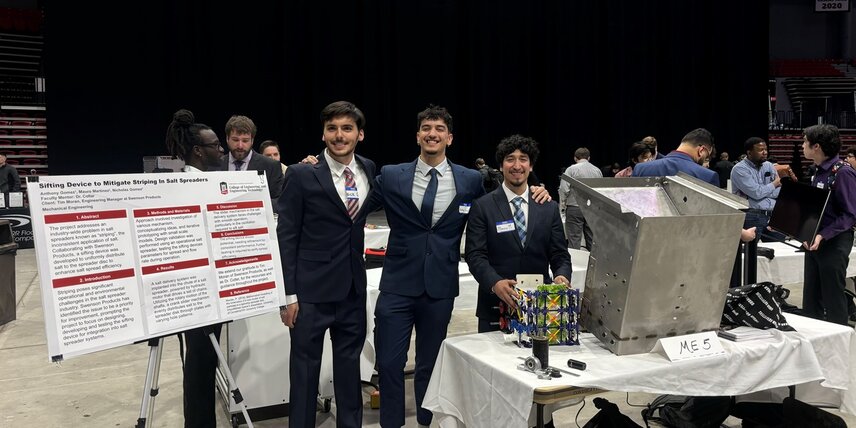

Anthony Gomez knows exactly what kind of impact a Swenson internship can have. After starting as part of a senior design project with Swenson during his final year at NIU, he took on a summer internship that led to a full-time role with Monroe Truck Equipment.

“Developing my own hopper extension prototype and getting our mechanism patented will always be one of the most memorable experiences I’ll have as a designer,” Anthony shared. “The fact that my project made a tangible difference for the R&D team—and ultimately for the customer—is something I’m incredibly proud of.”

Anthony’s experience is proof that when given the tools and trust to make an impact, interns can become invaluable members of the broader Aebi Schmidt Group family.

Investing in the Future, Delivering Results Today

At Swenson, interns aren’t sidelined—they’re immersed. From hands-on design work to real-world collaboration and problem solving, these emerging engineers help improve the products and systems that our customers rely on every day.

As the internship season draws to a close, it’s clear that the impact of these students goes far beyond temporary support. Their ideas, energy, and commitment have helped move projects forward and strengthen the foundation of our future workforce. As Tim Harn, CEO of Swenson Products, puts it:

“The success of our intern program is reflected in the quality of our products. These students contribute directly to the innovation and reliability our customers rely on. It's a win for them, for us, and for everyone who counts on Swenson.”

We’re proud to invest in the next generation of talent—and even prouder to see the difference they’re already making.

Learn more about Swenson Products and their role in Snow and Ice Removal.