Schmidt |Spreder|Stratos 1.7 - 3.0 m³

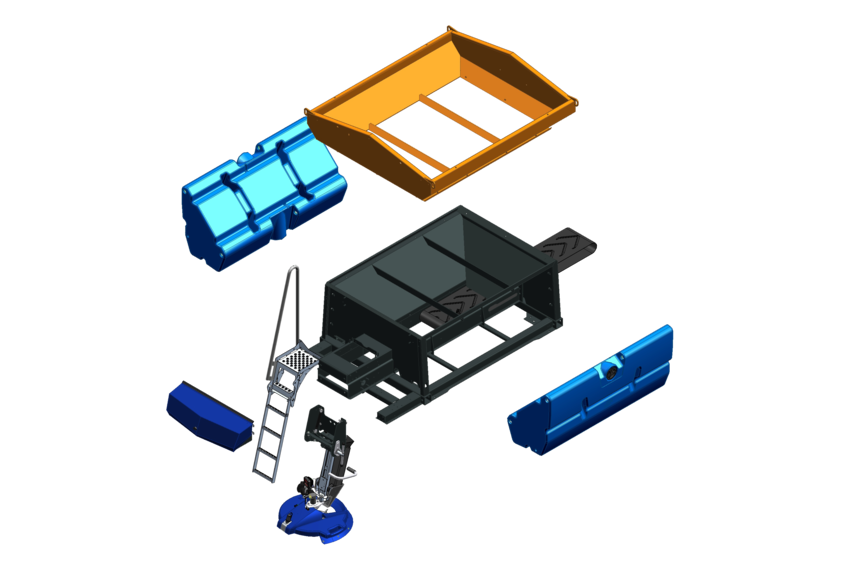

Modulbasert konsept

Det modulære konseptet i denne serien inkluderer både spredere med bånd- eller skruetransportsystem og de flate eller doble kammerspredere med dobbelt skruetransportsystem. Serien er optimalisert for kjøretøy fra 3,5 til 7,5 t.

Monterings- og demonteringssystemer

Hver av spredere kan utstyres med en av de tre monterings- og demonteringssystemene:

- Understell for demontering av ben eller fast montering

- RoRo-system egnet for full demontering

- Kulepunkt-ramme til 3 Unimog modeller (U216/U218, U218/U423, U427/U430)

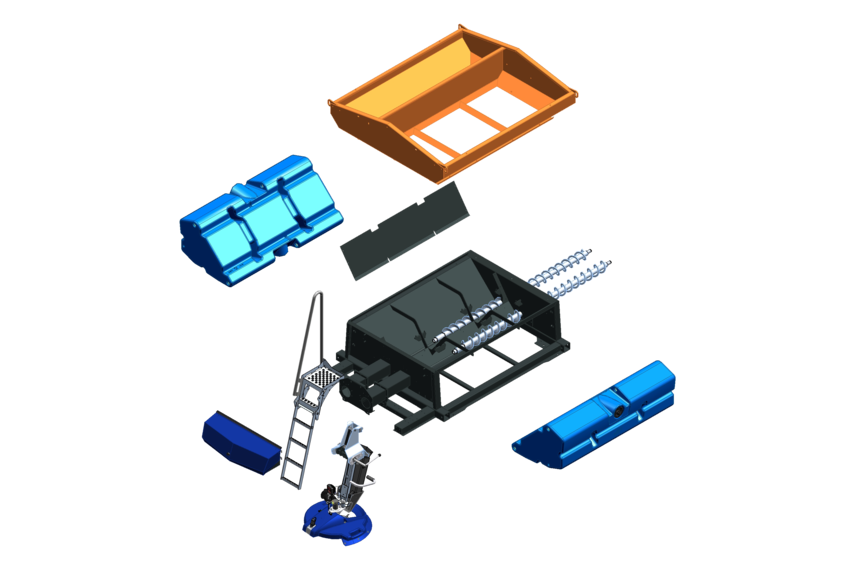

Doserings- og transportsystemer

Tre doserings- og transportsystemer er tilgjengelige:

- Det pålitelige transportbåndet, som passer til alle typer strømaterialer. doseringsluke med integrert klumpknuserfunksjon sikrer problemfri drift.

- Det robuste skruesystemet med variabel avstand på spiralen og doseringsskive. Dette sikrer jevn dosering og tømming av beholderen.

- Det doble skruetransportsystemet for en spesielt flatt beholderdesign og maksimal utnyttelse av kjøretøyets bredde. Takket være den nyforbedrede geometrien og den motsatte rotasjonsretningen til skruene har spredebildet blitt ytterligere optimalisert. Skruene i dobbeltkammerversjonen styres separat for å tillate forskjellig dosering av de to strømaterialene.

Befuktning

Sprederen er utstyrt med sidemonterte saltvannstanker med væskenivåindikator og en saltvannspumpe med beskyttelse mot tørrkjøring, og en Storz C-tilkobling er tilgjengelig for fylling og tømming av saltvannstankene bak på sprederen. Sugepunktet er plassert midt i tanken, noe som muliggjør drift i bratte områder uten problemer. Når du slår på saltlake, reduseres tørt materiale automatisk og distribusjonssystemets innstillinger justeres i samsvar med endringen i avisingsmiddelets sammensetning. Systemet oppnår høyt nøyaktighetsnivå, takket være integrerte sensorer for sammenligning av den faktiske kontra målverdien til kontrollløkkene.

Spredesystemer

Her brukes også det godt testede premiumblandingssystemet i Stratos-serien 4 - 12 m³. Den best materialstrømmen sikres av en polyetylennedløpstrakt med optimal utløpsvinkel. Spredematerialet treffer spredetallerken og fordeles optimalt til den spres ut. Dette skaper en homogen blanding, som dynamisk slippes ut som en buntet utkaststråle på en slik måte at effekten av vinden kompenseres for så mye som mulig.

Spredetallerkenens svingbarhet gjør det mulig å justere det symmetriske eller asymmetriske spredebildet manuelt eller elektronisk via kontrollpanelet. Takket være denne teknologien opprettholdes størrelsen på spredearealet, med et nøyaktig definert spredebilde og en spredebredde på 2 - 10m eller 3 - 12m.

Nytt i serien er Premium FS50 spredetallerken som gjør det mulig å spre en bredde på 2-6m eller 2-8m med en FS50-blanding.

Alternativer for drift

Det er også et utvalg av driftystemer. Stratos spredere kan bestilles med kjøretøyhydraulikk, dieselmotor eller Rotopower.

- Bilhydraulikk: Sprederen drives ganske enkelt av det hydrauliske systemet på bærerkjøretøyet.

- Motordrift: Dieselmotoren er integrert i fronten av sprederen, noe som reduserer den ekstra billengden som kreves.

- Rotopower: Den nødvendige drivkraften tas direkte fra bakhjulnavet og brukes til sprederen.

Kontroll- og informasjonssystemer

Schmidt EvolutionLine består av tre forskjellige driftskonsepter som gjør arbeidet enklere og mer effektivt. Takket være denne sofistikerte kontrollteknologien kan føreren styre alle funksjoner enkelt fra førerhuset og dermed reagere direkte på skiftende veiforhold. Avhengig av utstyrsvarianten er temperaturavhengig dosering også mulig (ThermoLogic) eller ruter kan planlegges på forhånd (Route Assistant).

Hvis du ønsker å overvåke, planlegge, kontrollere i sanntid, optimere eller for eksempel fakturere tredjeparter for aktivitetene til din Stratos, så bruk de digitale løsningene på vår Intelliops-plattform. IntelliOPS støtter deg i effektiv bruk av din individuelle maskin så vel som i et nettverk med flere maskiner, inkludert de av andre merker. Her kan du finne ut mer om våre digitale løsninger og hvordan du kan bruke dem på en måte som er modulær og tilpasset dine behov.