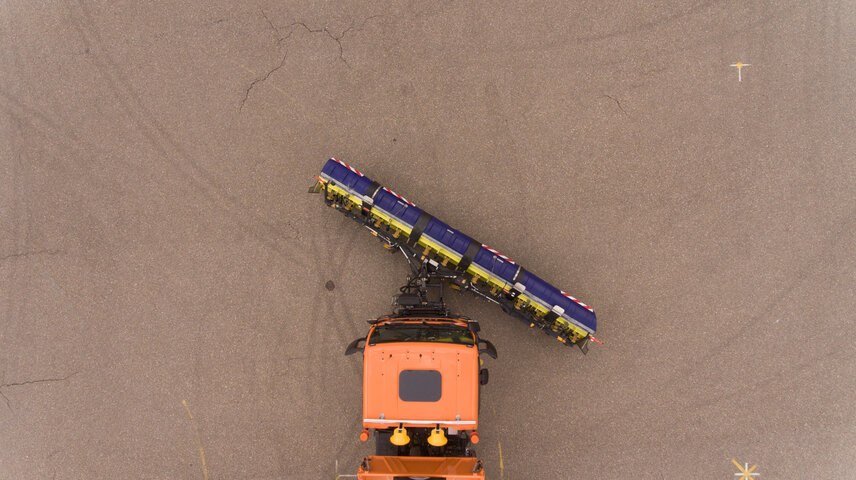

Schmidt |Snøplogen|Tarron HP-2W

Plogblad

De seks plogbladsegmentene, inkludert ytre vinger både høyre og venstre, tilpasser seg perfekt til konturene av veien takket være deres individuelle fjæring som, selv ved høye hastigheter, fører til svært ren snøklaring. De to ytre vingene kan justeres slik at forskjellige ryddebredder kan stilles inn.

Full utfoldet har snøplogen en enestående arbeidsbredde på 6,2 m. Når venstre vinge er brettet inn, reduseres arbeidsbredden til 5,1 m, og når høyre vinge er brettet inn, reduseres den til 4,5 m. Når begge vingene er foldet helt, er ryddebredden 3,4 m, mens vingene kan foldes hydraulisk i både transport- og ryddeposisjoner, noe som minimerer transportbredden. De heves automatisk under ryddeoperasjonen.

Overstyr sikkerhetssystemet

De seks segmentene av plogen tilpasser seg perfekt til veiens konturer, slik at den automatisk kan passere over små hindringer. Selv om plogen treffer et hinder, vil bare den ene plogskjæret som har direkte kontakt med den reise seg, resten av dem vil fortsette å snørydding.

Individuell oppheng på fire armer sørger for at skjæret kan springe tilbake og forhindre skader på plogen, mens hydrauliske ventiler åpnes automatisk ved en kollisjon, slik at vingene enkelt kan foldes inn.

Skjærekanter

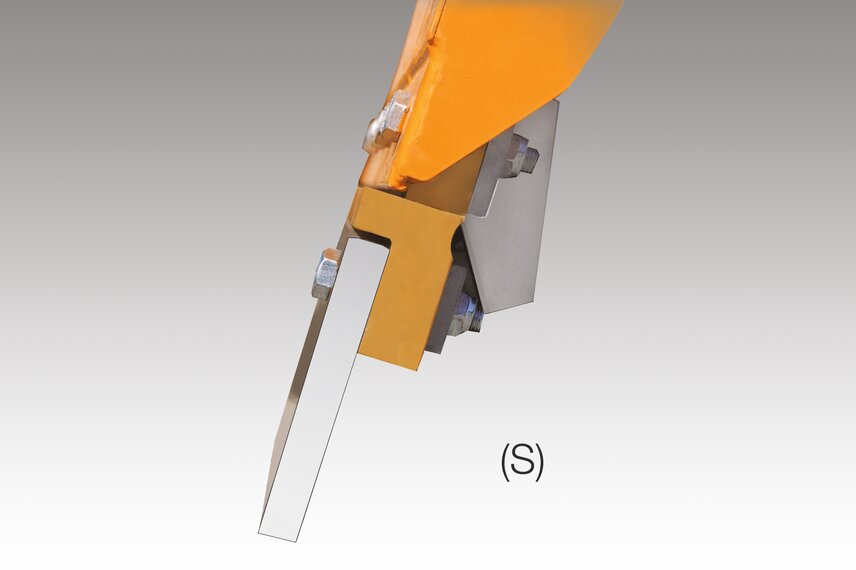

Stålskjærekant (S)

En flerbruks, kostnadsoptimalisert løsning for aggressiv rydding av hard og/eller kompakt snø. Stålskjærekanter er motstandsdyktige mot bøyning og vridning, noe som gir et rent resultat.

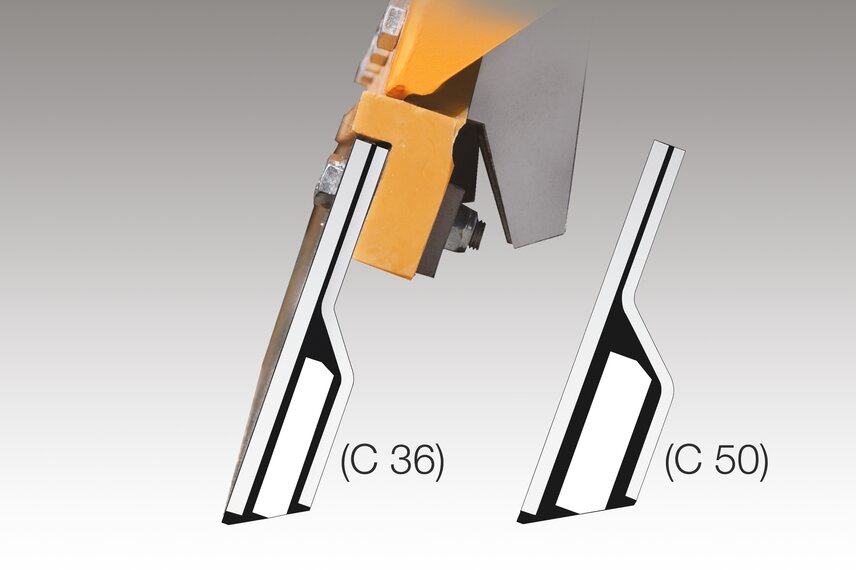

Combi skjærekant (størrelse 36 og 50) (C36 / C50)

En mer slitesterk skjærekant laget av stål, gummi og keramikk. Denne eggen er ment for aggressiv snørydding og kan være et godt alternativ dersom stålskjæret slites for raskt. Kombinasjonen av materialer sørger for støy- og vibrasjonsreduksjon.

TUCA SX skjærekant

Et toppmoderne snøplogblad med høy ytelse designet for langtidsbruk. Den patenterte Küper Wave Technology bruker en buet profil for å fjerne snø uten motstand. Separate wolframholdere innebygd i gummi og vulkanisert mellom foran og bak Hardox 400 stålplate gjør TUCA SX utrolig slitesterk.

GK 5 skjærekant

En GK-skjærekant gir mer effektiv snørydding med lengre levetid og mindre friksjon. Denne skjærekanten er laget av stål, gummi og korund og er derfor mer aggressiv enn en gummiskjær.

Løfte utstyr

En treleddet løfteanordning sørger for optimal kraftoverføring til bærekjøretøyet og spenningsfri løfting og senking av snøplogen. Dette gjør det mulig å få en stor løftehøyde og den er enkel å betjene.

Fiskesystem

To svingsylindere brukes for å gjøre sidejusteringer, som setter plogen i ønsket ryddeposisjon. Tilpasningssystem av svingvinkelen forhindrer at plogen vinkles til venstre side når det er fare for kollisjon med kjøretøyet. Enklere vedlikehold av plogen takket være de samme hydrauliske sylindrene for løfte- og fiskeinnretningen samt for betjening av vingene.

Kollisjonsbeskyttelse

Vingene foldes inn og ut hydraulisk, mens tre sensorer sørger for at de ikke skader kjøretøyet ved innfelling. Gjeldende arbeidsbredde er alltid markert med LED-posisjonslys.

Fungerende støtteenheter

Svinghjul

De trinnløst høydejusterbare styrehjulene med valgfrie sprutbeskyttere sørger for presis justering av snøplogen og gir passende aggressivitet under snørydding. De støtter rammen når du kjører over hindringer og forlenger levetiden til skjærekanten.

Glidesko

Alternativt kan det monteres vedlikeholdsfrie høydejusterbare glidesko. De er laget av svært slitesterk stål eller kombi.

Kerb deflektorer

Sidedeflektorene bidrar til å holde plogen fra å skrape mot fortauskanter og kanter ved rydding i urbane områder.

Snødeflektor

Tarron HP-2W er utstyrt med en snøbeskyttelse i polyuretan, som valgfritt kan heves for å redusere klaringsbredden. Tarron HP-2W kan utstyres med følgende varianter av snøskjermer:

Montering

Tyngdepunktet til Tarron HP-2W er bare 40 cm foran kjøretøyets monteringsplate, slik at den kan monteres på både tre- og fireakslede kjøretøy, forutsatt at kjøretøyet har en foraksel på minst ni tonn.

Alternativer

- Advarselsmerker, varselflagg eller LumiFog

- Sidelys LED / Ekstra arbeidslys på venstre eller høyre side

- LED-blinklys (oransje)