Schmidt |Feiemaskin|AS 990 / ASC 990

Rengjøringskonsept

Schmidt AS 990 / ASC 990 leverer perfekte feieresultater med stor flatedekning og sørger samtidig for trygge trafikkruter på hele flyplassområdet. Takket være den permanente magnetstaven, de to skivebørstene, blåsmunnstykkene som er montert på begge sider og den bakmonterte sugeenheten, rengjør maskinen store områder grundig og raskt i én og samme passering. Gjenstander av ulike typer og opprinnelse (FOD, metaller, smuss, løv osv.) fjernes på en pålitelig måte. Med den valgfrie og raskt utskiftbare væskesugerenheten tilbyr AS 990 / ASC 990 en komplett løsning.

Permanent magnetisk stang

Fjerning av fremmedlegemer (FOD) på en flyplass har stor innvirkning på sikkerheten og effektiviteten i flyoperasjoner. Derfor er den anbefalte permanente magnetstangen Schmidt PMB 2400 et uunnværlig verktøy for å fjerne magnetiske, spesielt farlige fremmedlegemer fra standplasser, taksebaner og rullebaner. PMB 2400 kan enkelt festes til den forhåndsmonterte monteringsplaten foran.

Skivebørster

De to skivebørstene (tilleggsutstyr) gjør det mulig å øke feiebredden og oppnå en mer omfattende rengjøring. Både bakkekontakttrykket og svingtrykket kan justeres pneumatisk og tilpasses optimalt til de spesifikke driftsforholdene. De integrerte vannsprøytedysene sørger for effektiv støvkontroll og garanterer trygge og rene arbeidsforhold.

Sugevifte med høy ytelse

Effekten til den høytytende sugeviften kan tilpasses optimalt til smussmengden. En hastighetssensor er innebygd i hydraulikken, som overvåker hastigheten/ytelsen til sugeviften. Trinnløs justering er også mulig. Hastigheten styres hydraulisk og kan justeres via kontrollpanelet. Den høytytende sugeviften forsyner de laterale blåsemunnstykkene med luftstrøm samt den bakre sugeenheten og den manuelle sugeslangen (ekstrautstyr) med sugeluft. Sammenlignet med en konvensjonell kilereim- eller tannremdrift krever sugeviften ikke noe vedlikehold. Pumpehjulet og huset er laget av slitesterkt metall.

Blåsemunnstykker

De valgfrie blåsemunnstykkene oppnår høy ytelse over hele arbeidsbredden og langs siden av lastebilen. Dette sikrer optimal rengjøring av flyplassområdet. Blåsemunnstykkene er tilgjengelige med pneumatisk høydejustering, noe som garanterer et enda bedre rengjøringsresultat i alle situasjoner.

System for suging og feiing

Den bakre sugeenheten har to sugekanaler (bredde: 2 x 1 150 mm), som er luftstrømoptimaliserte og belagt på innsiden med en varmvulkanisert slitasjebeskyttelse som standard. Dette sikrer mindre friksjon og mindre slitasje. Den bakre sugeenheten har en symmetrisk vektfordeling for optimalisert feieresultat. Feiemønsteret kan også justeres trinnløst fra utsiden, og har en slitasjeindikator med fargeskala.

Rullebørste

I tillegg til de to sugekanalene brukes en feierulle for raskere feiing (mekanisk feiing). Denne strekker seg over hele arbeidsbredden og heves automatisk når man støter på hindringer. Feiehastigheter på opptil 40 km/t er mulig.

Integrert avfallsklaff

I standardversjonen er det integrert en søppelklaff i den bakre sugeenheten. Den fungerer pneumatisk og kan betjenes fra førerhuset. Dermed kan større avfall samles opp. Som tilleggsutstyr kan det konfigureres en væskeklaff for bedre oppsamling av væsker.

Avtrekksluftdiffusor

De to sugekanalene suger luft som inneholder avfall, inn i beholderen. Avfallet skilles ut i beholderen ved hjelp av tyngdekraften. Avtrekksluften slippes ut oppover over beholderen. En diffusor kan installeres i taket for å regulere luftstrømmen. For enklere rengjøring kan den svinges pneumatisk.

Væskesugeenhet

Væskesugerenheten er spesialkonstruert for oppsamling av væsker som vann eller avisingsmidler (for eksempel optimal glykolabsorpsjon på 96 til 99 %). Den leveres med to sugekanaler (bredde: 2 x 1250 mm), som har en luftstrømoptimalisert utforming og som standard er belagt med et varmvulkanisert slitasjebeskyttende belegg på innsiden. Dette sikrer lavere friksjon og mindre slitasje. Væskesugerenheten kan monteres enkeltvis eller i kombinasjon med den bakre sugeenheten.

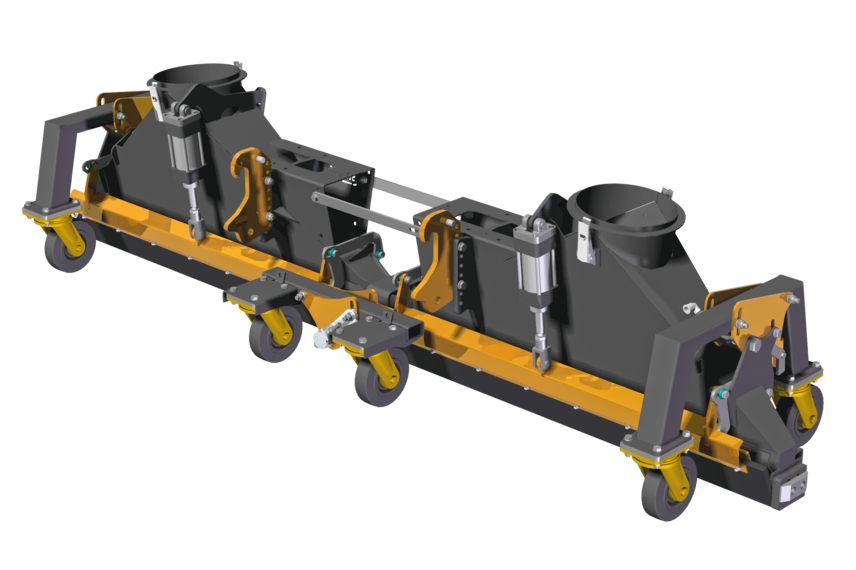

System for feste av sugeenhet

Den bakre sugeenheten (A) og væskesugerenheten (B) kan monteres hver for seg bak, og væskesugerenheten kan også monteres mellom akslene enkeltvis (C) eller i kombinasjon (D) med den bakre sugeenheten. Sugeenhetene er festet via en fleksibel løfteanordning som er uavhengig av understellet. Dette muliggjør optimal tilpasning til underlaget under drift. Løpehjulene med integrert returmekanisme styrer sugeenhetene pålitelig over veibanen. Med det valgfrie hurtigbyttesystemet fra Aebi Schmidt kan den bakre sugeenheten byttes ut med væskesugerenheten uten bruk av verktøy på bare noen få minutter (A+B).

Hopper

Den generøst dimensjonerte beholderen har en kapasitet på 9,5 m³ og er utstyrt for store mengder avfall. Som standard er beholderens gulv laget av rustfritt stål. Beholderen kan vippes hydraulisk og gir sikker tømming takket være en vippevinkel på 52°. Beholderen kan vippes uten å starte hjelpemotoren, og betjenes via en separat fjernkontroll som oppbevares i en vanntett oppbevaringsboks.

Vanntank

Den korrosjonsbestandige vanntanken er montert mellom førerhuset og hjelpemotoren for å redusere støy, og den har en lett tilgjengelig rengjøringsåpning. Den har en kapasitet på 2 000 liter og er laget av polyetylen (PE). Den tilhørende vannpumpen med et maksimalt trykk på 10 bar ved 37 l/min er hydraulisk drevet og kan trygt kjøres tørr. For optimal støvkontroll er det montert vannspraydyser foran sugeenheten, i sugekanalen og sugerøret samt på de valgfrie skivebørstene. Vinterfunksjonen gir optimal beskyttelse takket være automatisk utblåsing av hele vannsystemet (frostbeskyttelsesfunksjon). En ekstra vanntank på 2 000 l kan legges til som ekstrautstyr.

Konfigurasjonsmuligheter

Utstyret som anbefales av Aebi Schmidts eksperter inkluderer permanent magnetstang, skivebørster og to blåsemunnstykker. I tillegg anbefaler vi den bakre sugeenheten med hurtigbyttesystem for væskesugerenheten (ekstrautstyr), som utmerker seg ved sin fleksibilitet og vedlikeholdsoptimaliserte design. Den siste funksjonen er avtrekksdiffusoren som er installert i beholderen, og som er konstruert for en sikker arbeidsprosess. Vi tilbyr også følgende konfigurasjonsalternativer som standard:

Utvidede alternativer

- Manuell sugeslange

En manuell sugeslange kan monteres på bakdøren på beholderen for rengjøringsarbeid i sluk, vannsjakter osv. Slangediameteren er 200 mm, og kontrollenheten er festet direkte til den manuelle sugeslangen. - Slangetrommel med rengjøringsslange

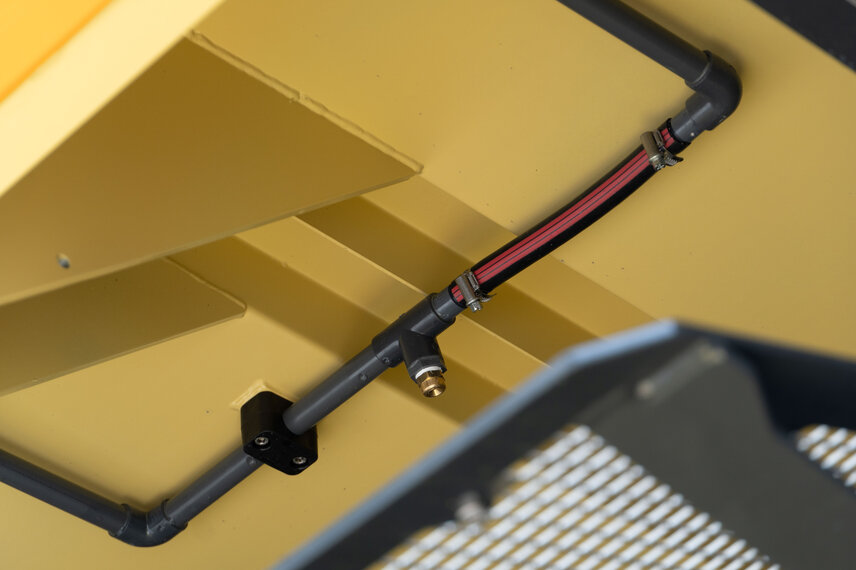

Denne gjør det mulig med grovrengjøring av beholderen eller feiemaskinen etter tømming. Vannslangen er 10 meter lang og har en justerbar vannsprøytedyse. Vanntilførselen skjer via den hydraulisk drevne vannpumpen. - Rengjøringsenhet for løvsikt i beholderen

Rengjøringsenheten for løvsikt gjør det enklere å rengjøre beholderen. Et vannsprøyterør med vannsprøytedyser muliggjør enkel og optimalisert rengjøring av bladristen og området over bladristen. - Vannuttak på den bakre beholderdøren

For å kunne tømme ut overflødig vann eller avisingsvæske ved behov (f.eks. før beholderen er helt tømt), er det montert et vannutløp på bakdøren til beholderen. - Overvåking av bakre område

Et kamera er montert på beholderdøren. Det slås på automatisk så snart reversgiret legges inn. Bildet vises på displayet på kontrollenheten. - Uttrekkbare sugekanaler på siden

I tillegg til sugeenhetene kan det monteres to sugekanaler til venstre og høyre foran bakakselen. Dette øker sugebredden med 500 mm i hvert tilfelle. Sugekanalene er pneumatisk betjent og har et sideveis justeringsområde på 320 mm. Det er mulig å suge når sugekanalen er trukket ut eller inn til siden. De integrerte vannspraydysene sørger også for optimal støvkontroll.

Spesialversjon: Schmidt ASC 990

Schmidt ASC 990 rengjør også flystativ ved hjelp av en blanding av vaskemiddel og vann. Det tilsmussede området fuktes med rengjøringsemulsjonen ved hjelp av den ekstra spraybaren foran skivebørstene. Deretter behandles og rugges overflaten opp med skivebørstene. Det løsnede materialet samles opp i beholderen via den bakre sugeenheten. Denne versjonen er spesielt egnet for intensiv rengjøring av trafikkerte områder.

Høytrykksrengjøringsutstyr med roterende sprøytedyser

En effektiv høytrykksspyler, som arbeider med opptil 200 bar og 70 l/min, kan også monteres foran væskesugerenheten. Dette gjør det mulig å rengjøre over en bredde på ca. 2 400 mm samtidig som vann og smuss suges helt ut. Dette alternativet forbedrer resultatene ytterligere.