Schmidt |Salt solution station|P 2000

Construction

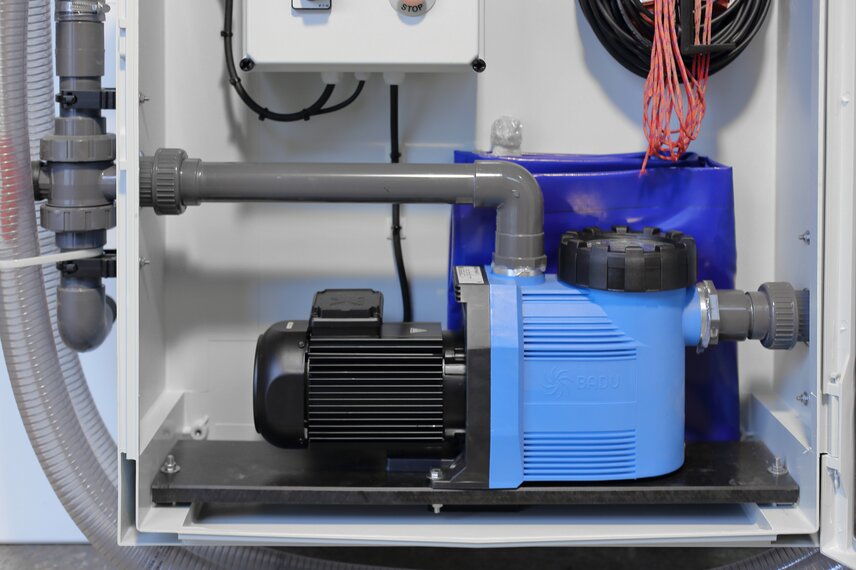

The P 2000 features a solid construction, simple operation and reliable functions, with few moving parts. In addition to a mixing tap, the system has a dissolving/filling pump and an on/off switch. The station's entire housing is made of durable polyester, while it has a capacity of around 2,000 litres of unsaturated solution (20-21%) per batch.

Preparation of the salt solution

Wet salt is suitable for almost all winter weather conditions down to a temperature of -10°C. However, the decisive factor is the brine required for pre-wetted salt spreading. Too low a concentration can cause freezing, while too high a concentration results in a saturated solution that can lead to crystallisation and malfunction of the system.

The P 2000 works according to the "flow around principle". This involves dissolving salt until a saturated solution is formed, which is then diluted again until the concentration has the desired properties, thus ensuring that crystallisation is impossible.

The preparation of the salt solution is quick and easy. The dissolving compartment is filled with around 500kg of salt and the water tank with about 2,000 litres of water. The pump can then be switched on to start the dissolving process. After about 20 minutes, 2,200 litres of unsaturated salt solution is ready for use. If the solution is not used up immediately or is pumped into a storage tank, the P 2000 can also act as a buffer.

The production of an unsaturated solution has two very important advantages:

Trouble-free operation: No crystallisation can take place, which is important for the trouble-free operation of the spreader and the equipment.

Circulation is unnecessary: The unsaturated solution makes regular circulation unnecessary as the solution cannot settle at this concentration.

Options

- Concentration analyser

- Tarpaulin

Note

Local regulations regarding connections, authorisation, operation, underground drainage and storage must be observed at all times.