Schmidt |Jet sweeper|CJS-DI

Clearing process

Back to blacktop in a single work step

Four process steps combined in a single operation and the runway is ready for flight operations again.

- The snow plough clears the majority of the snow to the side

- The brush roller clears away the remaining snow and slush

- The blower unit generates a powerful jet of air that sweeps across the entire sweeping width, removing any remaining moisture

- The build-up spreader/sprayer ensures de-icing or prevents against building

Snow plough

Clean and aggressive clearance is achieved with the Schmidt MS Tarron airport snow ploughs, such as the MS 56.2 N. These are designed for fast snow clearance at airports and offer outstanding performance with optional fine clearing bar, ejection stop or low blade shape.

Sweeping unit

The sweeping unit is mounted between the vehicle axles, while the drive of the brush is hydrostatic. The brush is optimally adapted to the sweept surface and achieves a very good clearing result. The sweeping pattern adjustment of the brush is adjusted automatically and continuously via twin castor wheels.

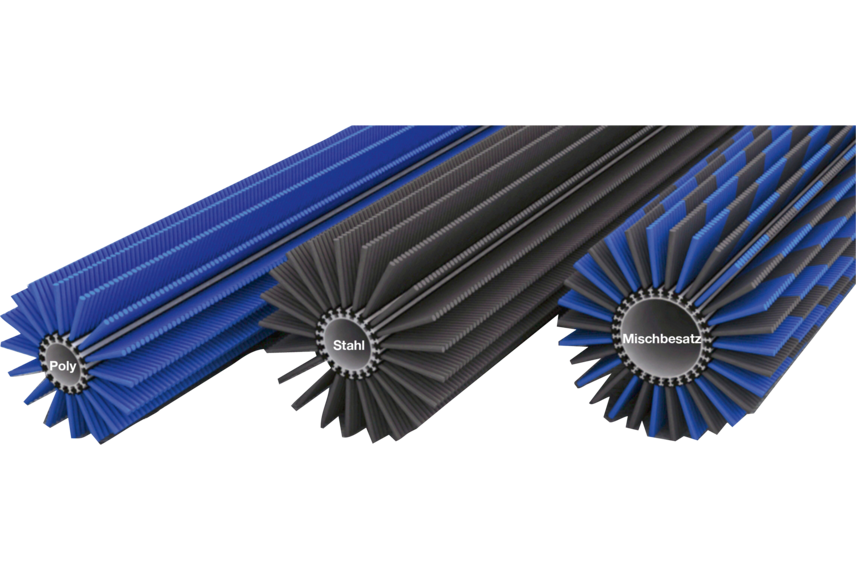

Brush designs

The CJS-DI has a 16-piece cartridge system with plastic [1], steel [2] or mixed bristles [3] and is also available as an 18 or 21-piece system. The 21-piece design produces less air turbulence with the denser bristle material, which ensures better clearing performance and a longer brush life at the same speed and with more brush strips.

Blower unit

The high-performance blower is driven hydraulically by the auxiliary engine via a variable displacement pump. The blower can be switched on and off by swivelling the pump. The blower unit is optimally designed to spread the large air capacity. The air speed is virtually constant across the entire working width. The blowing nozzle can be raised and lowered hydraulically.

Mounted spreader/sprayer

With the spreader/sprayer, de-icing can be delivered both preventively and curatively. The entire vehicle width is covered by a spray bar, while further working widths can be achieved with additional jet nozzles. The drive for the spreader/sprayer is provided by the carrier vehicle's hydraulics.

Carrier vehicles

As standard, the CJS-DI seamlessly mounts onto the MAN TGS 18.320 chassis type carrier vehicle. This carrier vehicle features a turning circle diameter of 18 meters and offers the option for additional rear axle steering for enhanced agility. The basic equipment and the exhaust emissions of the carrier vehicle must be selected specifically to meet the standards of the customer and the relevant country.

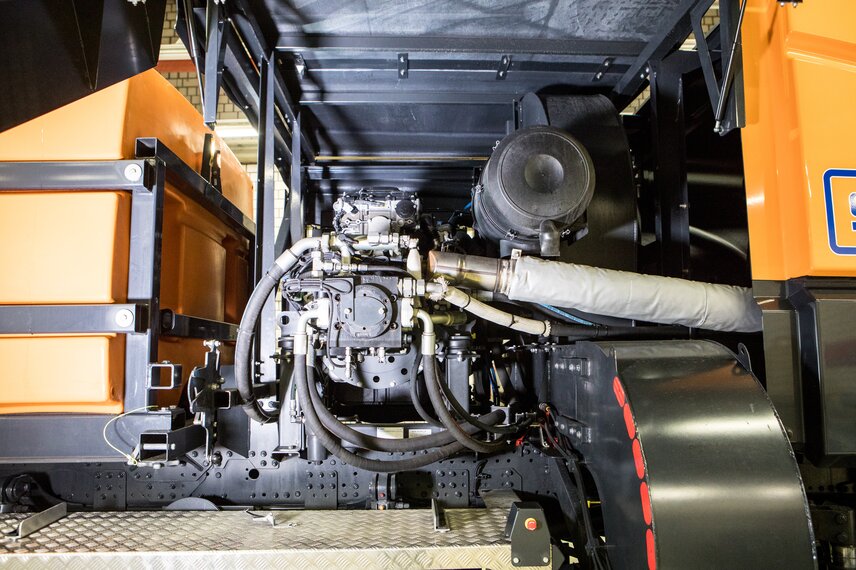

Drive

The drive motor drives the hydraulic pumps for operating and controlling the sweeping unit and blowing unit. The snow ploughand the mounted sprayer/spreader are controlled by a hydraulic system driven by the carrier vehicle's engine. The CJS-DI's hydropneumatic chassis offers the operator additional comfort in the field.

Motion control

Both impulse and synchronous control are possible for the snow plough, sweeping unit, blowerand rear mounted spreader/sprayer. On the one hand, this allows particularly efficient clearing processes via synchronous control. On the other, it also allows response to specific situations such as adjustment of the snow plough by means of individual, impulse control.

Display

State-of-the-art control technology is an important step in the safe and efficient clearing of airport tarmac. Logical and intuitive menu navigation and automatically controlled processes help to support drivers by ensuring that concentration remains focused on the clearing operation. The display indicates the operating hours data when the machine is at a standstill; information about the engine speed, brush speed and blower output can be called up when the engine is running. The display also provides a comprehensive overview of fault or error messages.

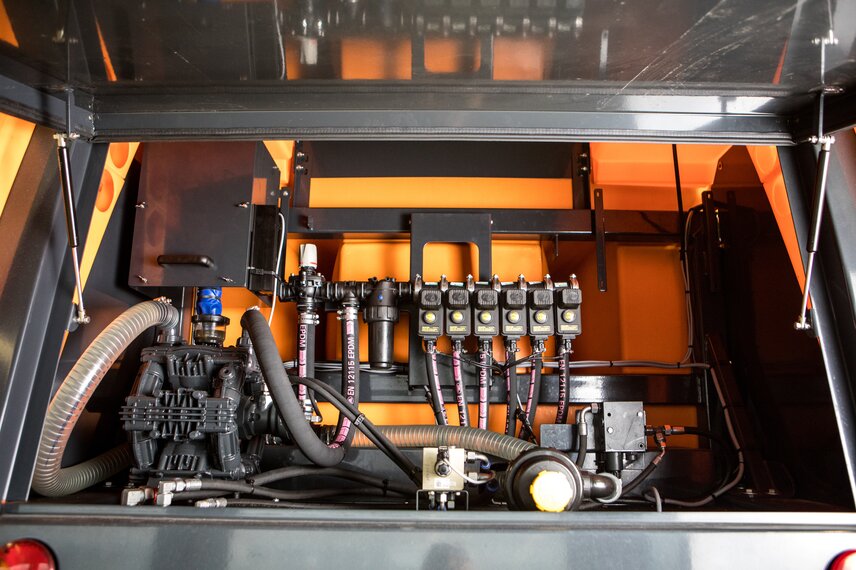

Smart Service Concept

The Smart Service Concept equals easier maintenance. It allows free access to all important components and low service time due to the ease of access to the components. In addition, the CJS-DI has a practical mounting bracket for the control panel on the control cabinet for service and workshop use. The optimised wiring harness layout ensures high quality standards and reduced service requirements. At the same time, the air intake underneath the bonnet ensures less air filter contamination.