General Winter Preparation

Start early—most technicians recommend beginning two to three months before the first snow to account for parts lead times and to get ahead of demand. As Hunter put it, “Having normal wear items in stock before the season begins reduces downtime when you need equipment the most.”

Key steps include:

- Running equipment through all systems to confirm functionality.

- Checking for leaks and greasing all lubrication points.

- Training or refreshing operators on equipment handling.

- Addressing minor issues now before they grow into bigger problems.

Pro tip: Don’t wait until the forecast calls for snow. As Sam noted, “Summer services should be complete well before winter. If you wait until the day before a storm, you’ll miss critical checks.”

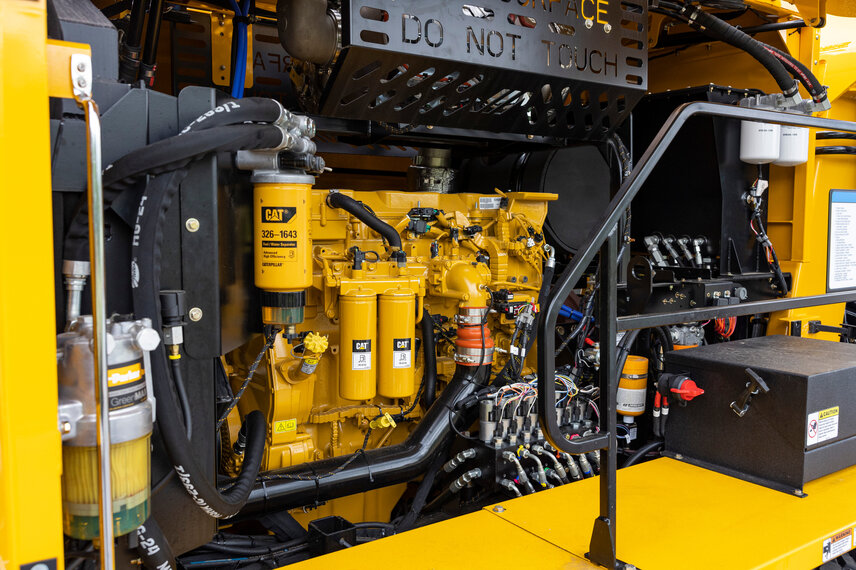

Equipment Inspections & Maintenance

When inspecting, technicians recommend starting with safety-related systems—brakes, hydraulics, electrical components, and tires—then moving to consumables such as cutting edges, broom bristles, and impellers.

Hidden but critical areas:

- Broom spines and boom grease points – often overlooked but essential for smooth operation.

- Caster wheels and weight transfer hitches – small components that play a big role in performance.

Signs it’s time to replace instead of service:

- Abnormal noise or vibration.

- Visual wear beyond service specs (e.g., broom bristles under 3” from the end plate).

- Fluid leaks are classified as Class 2 (drops forming).

Fluids & Engine Care

Cold weather puts extra strain on fluids and batteries. Our technicians recommend:

- Using Dex III ATF, 75W90, and 15W40 as seasonally appropriate.

- Checking coolant freeze points.

- Replacing fluids annually or per the service manual.

- Confirming batteries can crank in warm weather—because if they struggle then, they’ll fail in the cold.

Sam also stressed the importance of fuel prep: “Use blended fuel to prevent gelling in cold weather.”

Brushes, Plows & Sweepers

Brushes are made to wear—but checking patterns and starting fresh can prevent downtime.

- Replace when bristles are less than 3” from the end plate.

- Aim for a 2–4” broom pattern, not 12” (which causes unnecessary wear).

- Verify plow heights, impeller alignment, and cutting edges well in advance.

As Mac put it: “Start fresh and order stock before demand rises. Consumable parts go fast once the season hits.”

Preventative Programs & Operator Practices

Preventative programs extend equipment life and cut downtime. Schedule maintenance in the off-season so the “truck doesn’t schedule it for you” at the worst possible time.

For daily operations:

- Pre-trip inspections before each storm.

- Check broom patterns before every snow event.

- Inspect tire tread depth—even if equipment isn’t road-bound.

- Park equipment inside when possible or use block heaters to support overnight starts.

Common Issues & Troubleshooting

The most common winter problems? Hydraulic leaks, worn brushes, battery failures, and even accidents from rushed prep. Prevention is the key: thorough pre-checks, lubrication, and training.

When issues do arise, listen for unusual vibrations or noises—often the first indicator of a bigger failure ahead.

Final Word from the Technicians

Preparation isn’t just about checklists—it’s about mindset. Sam summed it up well: “Know your snow. Understand what you’re driving on, read the manual and get the training you need.”

Winter is demanding, but with the right maintenance and attention to detail, you can keep your airport’s snow and ice removal equipment reliable, safe, and ready for every storm.

Don’t wait for the first snow to find out your equipment isn’t ready. We’re here to help. Reach out today with general maintenance questions or to schedule time with our Certified Technicians.