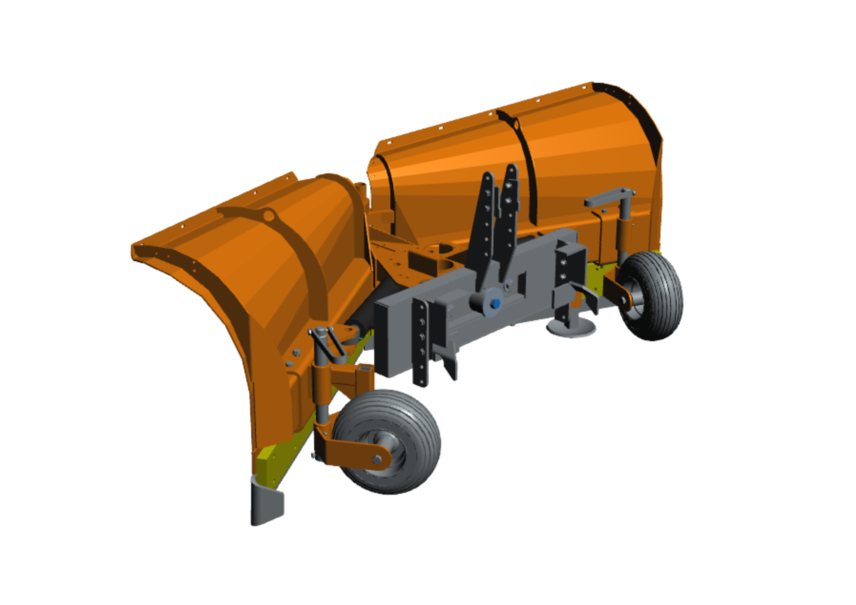

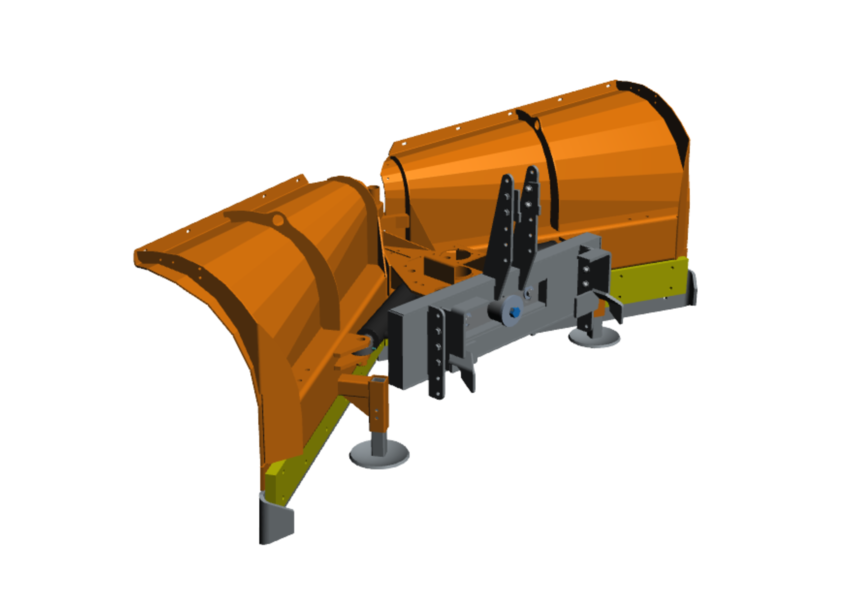

Schmidt |Snow plough|Tellefsdal VPL

Plough blade

The VPL consists of a right and a left ploughshare, connected in the middle with an A-frame by means of pivots and a pin, which forms a stable base for difficult and heavy snow clearance. The geometrically shaped and steeply inclined ploughshare ensures optimum snow ejection.

Override security system

The VPL easily overcomes ground obstacles even under difficult operating conditions. This is due to the automatic override security system with shock absorber rails, which act as a connectio to the scraper bars. The spring-reinforced shock absorber rail between the cutting edge and plough blade absorbes the the high impact energy and ensures at the same time minimal noise, very smooth running and aggressive snow clearance.

Hydraulics

All functions are hydraulic and can be operated from the cab. Each ploughshare is operated by a standardised hydraulic cylinder and swivel it against a mechanical stop when fully engaged. In the standard version, the VPL is suitable for vehicle hydraulic systems with two control cells for snow plough operation. Pressure relief valves and accumulators in the hydraulic system protect and dampen the shares.

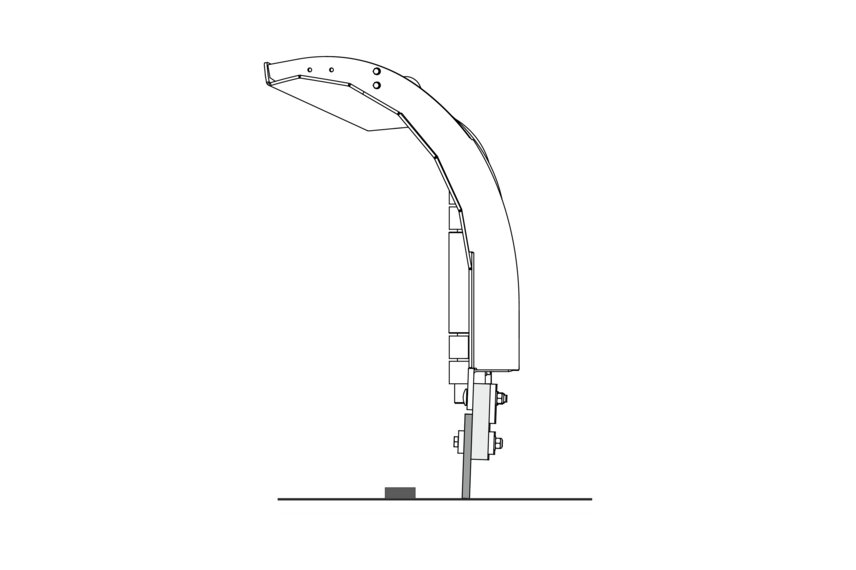

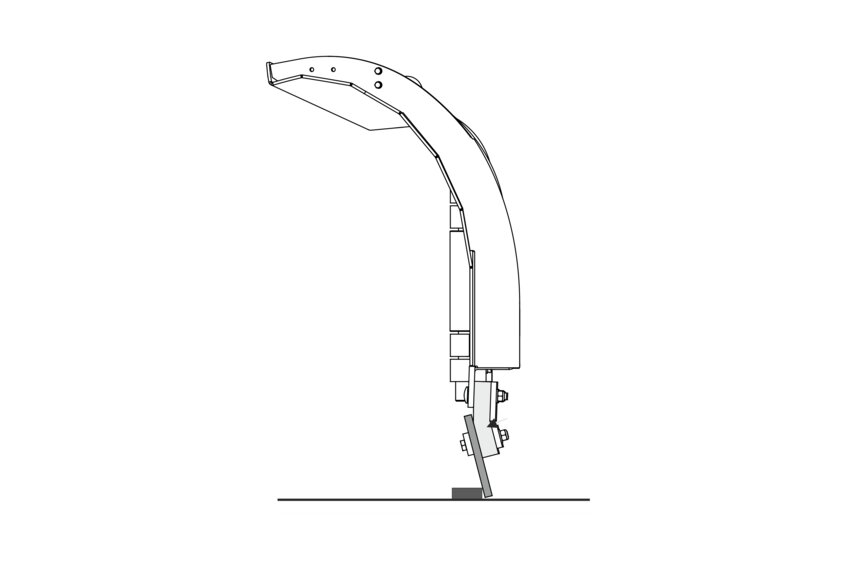

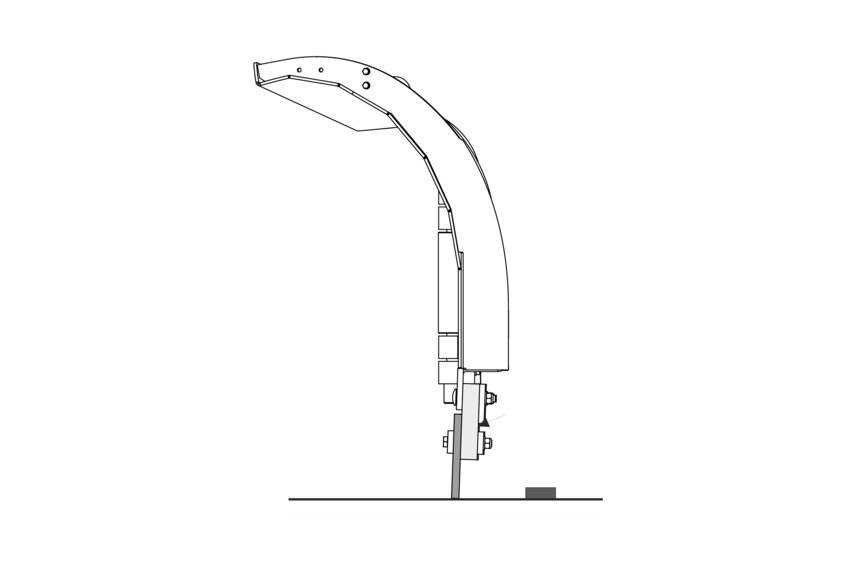

Mounting

The VPL series is equipped with a mounting plate as standard. The optional lifting system with country-specific mounting plates enables adaptation to vehicles with both lifting systems or mounting plates and allows changeover within minutes. The VPL is suitable for mounting on both work vehicles and front loaders.

Cutting edges

Slush cutting edge PUR

These cutting edges allow for more efficient snow clearance without causing any damage to either the surfaces or to the floor lamps. The PUR cutting edges represent a very high slide resistance and low noise level.

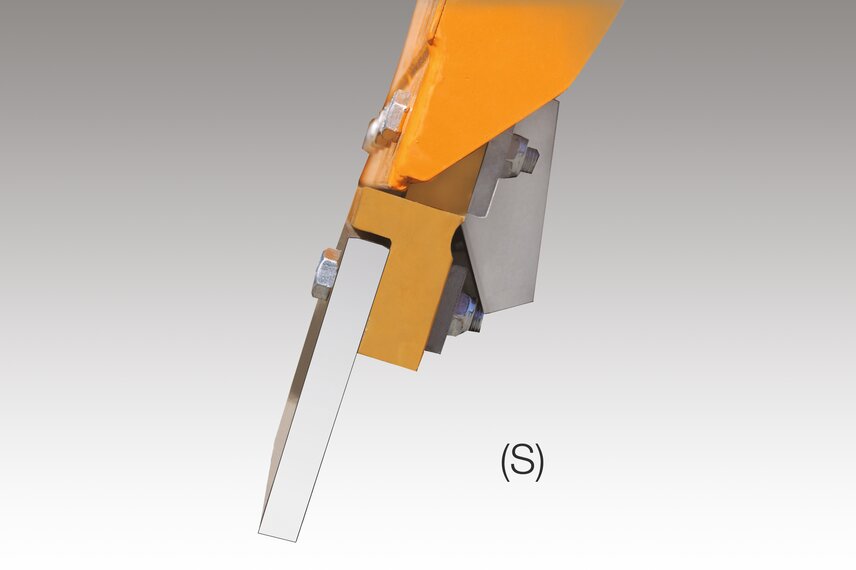

Steel cutting edge (S)

A multi-purpose, cost optimised solution for aggressive clearing of hard and/or compact snow. Steel cutting edges are resistant to bending and twisting, giving a clean result.

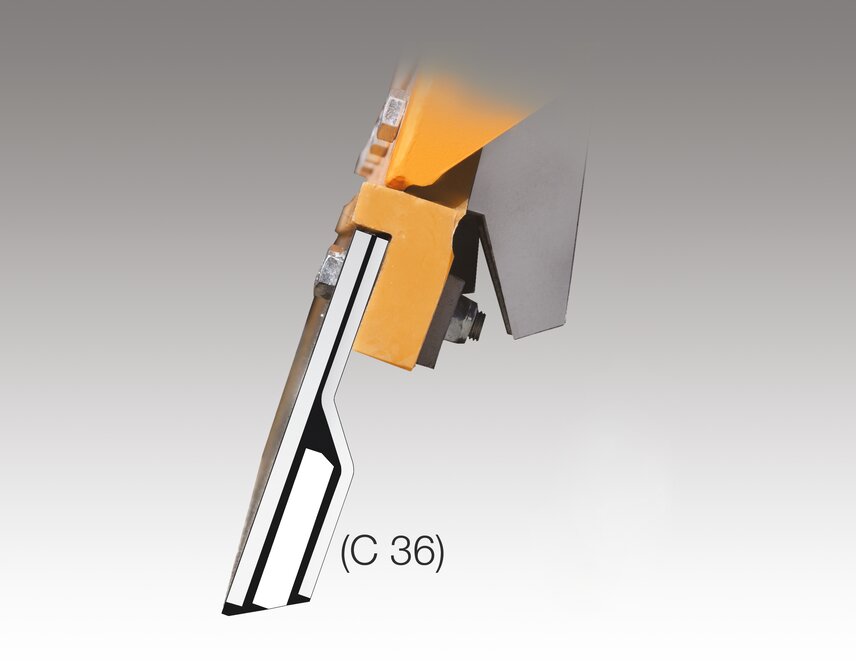

Combi cutting edge size 36 (C36)

A more durable cutting edge made of steel, rubber and ceramic. This cutting edge is meant for aggressive snow clearing and can be a good alternative if the steel cutting edge is wearing out too fast. The combination of materials ensures noise and vibration reduction.

Rubber cutting edge (50 mm) (R)

A good solution for use on urban roads and special properties such as parking lots. Due to the flexible and elastic characteristics of rubber, it glides smoothly over the surface. A rubber cutting edge is especially efficient when clearing snow slush.

GK 5 cutting edge (GK 5)

A GK cutting edge allows for more efficient snow slush clearing with longer service life and less friction. This cutting edge is made of steel, rubber and corundum and is therefore more aggressive than a rubber cutting edge.

Working support devices

The castor wheels ensure precise adjustment of the snow plough and provide appropriate aggressiveness during snow clearing. They support the frame when driving over obstacles and extend the service life of the cutting edge. Alternatively, maintenance-free height-adjustable sliding shoes can be fitted. They are made of highly wear-resistant steel or combi.

Snow deflector

An optimised rubber snow deflector prevents poor visibility due to snow swirling up to the windscreen of the vehicle. The rubber shield directs the air stream along with the snow dust to the side. Rubber protection is used mainly during slow clearing of wet and heavy snow. Thanks to its great flexibility, the splash guard is not easily damaged. It is simple and cost effective option.

Options

The VPL can be equipped with a "Super Swing" feature which allows the ploughshares to be swivelled diagonally to the right, left or only to one side. Further options including sliding shoes, trailing wheels and snow dust protection are also available.