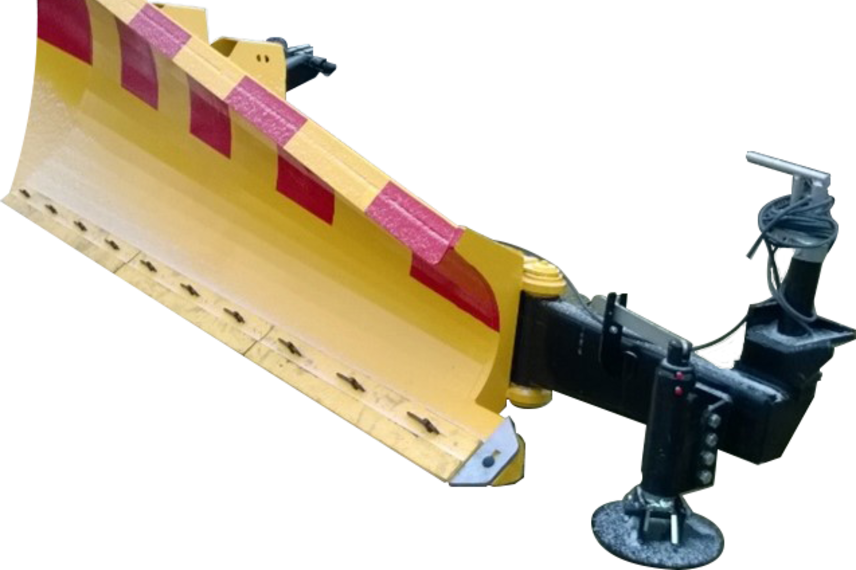

Arctic |Snow plough|SHJ

Side plough wing

Smaller side plough models have a fixed blade with an attack angle of 42°. Larger ones are mostly used on highways and can be equipped with the iFlex blade system with a less aggressive attack angle of 51°.The iFlex blade system consists of one-foot elements which precisely follow the road surface, as well as providing an outstanding ploughing result on impacted snow and roads with tracks or potholes. The wing structure is made of ultra-strong steel.

Snow bank cutting

The plough wing was originally designed for use not only with trucks, but for graders at snow bank cutting works. Nowadays, snow cutting is needed on graveled roads with high snow banks during the spring. The SHJ is ideal for cutting snow on the same level as the road surface. However, it can be tilted downwards into a negative inclination angle to move snow at the very bottom of the road bank.

SHJ J side ploughs: Flexible blade system

The SHJ J range consists of two different wing sizes, 16 and 18 feet, which differ from standard side ploughs thanks to the flexible iFlex blade which follows the contours of the road surfaces precisely, while preventing vibration passing onto the wing and back to the base truck. The SHJ J side plough models complement the low-noise front ploughs, significantly reducing the noise of the entire road maintenance unit. The iFlex blade is divided into 305 mm long flexible sections, which gives the side plough an excellent ploughing result over the entire wing. The working width of the wing can be readily adjusted while driving.

Attachment system

By being attached to to the truck’s subframe in two places and connected with a longitudinal beam, the force is distributed evenly along the frame to ensure better handling of the truck during ploughing.

The SHJ side plough attachment system is very compact in terms of necessary space and consists of two parts – a front attachment requiring 300mm of space into the wheel base and a rear attachment requiring 200mm space at the rear of the subframe. On one hand this ensures optimum force distribution along the whole subframe, on the other it leaves space to have additional equipment mounted within the wheel base, such as a scraper or underbody brush.

All side plough wings with attachments are designed so that they will work together in perfect harmony with scrapers.

Rear attachment has models with integrated underrun beam.

Protection systems

Safety protection of the plough starts with a hydraulic safety valve integrated into a swiveling cylinder. In the case of overloading caused by a collision, the shock valve releases oil back to the tank and the wing moves back towards the truck. At the same time, the longitudinal beam has a safety pin which cuts away for rapid wing closing, while the beam itself will absorb the impact and bend to an “S” shape to take the impact energy. All these stages of protection aim to save the truck’s frame as this is the most expensive element.

Snow visor

The snow visor is made from robust and flexible polyurethane and continues the wing’s cylinder shape. It helps to roll snow inside of the wing and eject it quickly with the help of aerodynamic forces. This prevents snow obscuring the driver’s windshield and mirrors, making ploughing safe, comfortable and relatively risk-free.

Warning lights system AM PRO

Over the years, a reliable, powerful, and safe warning light system has been developed together with road authorities, police and drivers to make usage of the side plough as safe as possible for all road users. Today’s system consists of three beacons, five strobe lights and one red marking light at the end of the wing. Experience of use of this system in many countries has shown a dramatic drop in accidents involving other road users.

Accessories

- Wear disk support

- Gel-filled wheel support

- AM PRO warning light system

- iFlex blade system for highway models

- Noise reduction set

- Steel blade set

- Hard metal blade set