Schmidt |Sopmaskin|eSwingo 200⁺

Miljövänlig och elektrisk

- eSwingo 200+ kännetecknas av en helt elektrisk drivenhet. Hjärtat i drivningen är högspänningsbatteriet med en batterikapacitet på 75 kWh, som består av två enskilda batteripaket. De kraftfulla batterierna möjliggör driftstider på upp till 10 timmar utan laddning. Den integrerade snabbladdaren ombord garanterar full laddning på bara fyra timmar.

- Ett batterihanteringssystem (BMS) övervakar och styr kontinuerligt batteriet, som består av högkvalitativa komponenter, laddnings- och urladdningsprocesserna samt temperaturen och bidrar på så sätt till en lång livslängd och största möjliga säkerhet.

- Drivenheterna för alla huvudfunktioner - framdrivning, fläktdrivning, hydraulpumpdrift och luftkonditionering i förarhytten - har elektrifierats. Den elektriska drivenheten erbjuder högre effektivitet, optimala effektegenskaper och hög prestanda med låga underhållskrav.

- Endast en elmotor, som är direkt ansluten till bakaxeln, används för drivenheten och ger hastigheter upp till 50 km/tim, medan ljudnivån är många gånger lägre än för ett dieselfordon. Ett elektriskt parkeringsbromssystem med backstartassistans garanterar säker och bekväm körning.

- Batterikapacitet på 75 kWh

- Full laddning på bara fyra timmar

- Hastigheter upp till 50 km/tim

Sopteknik

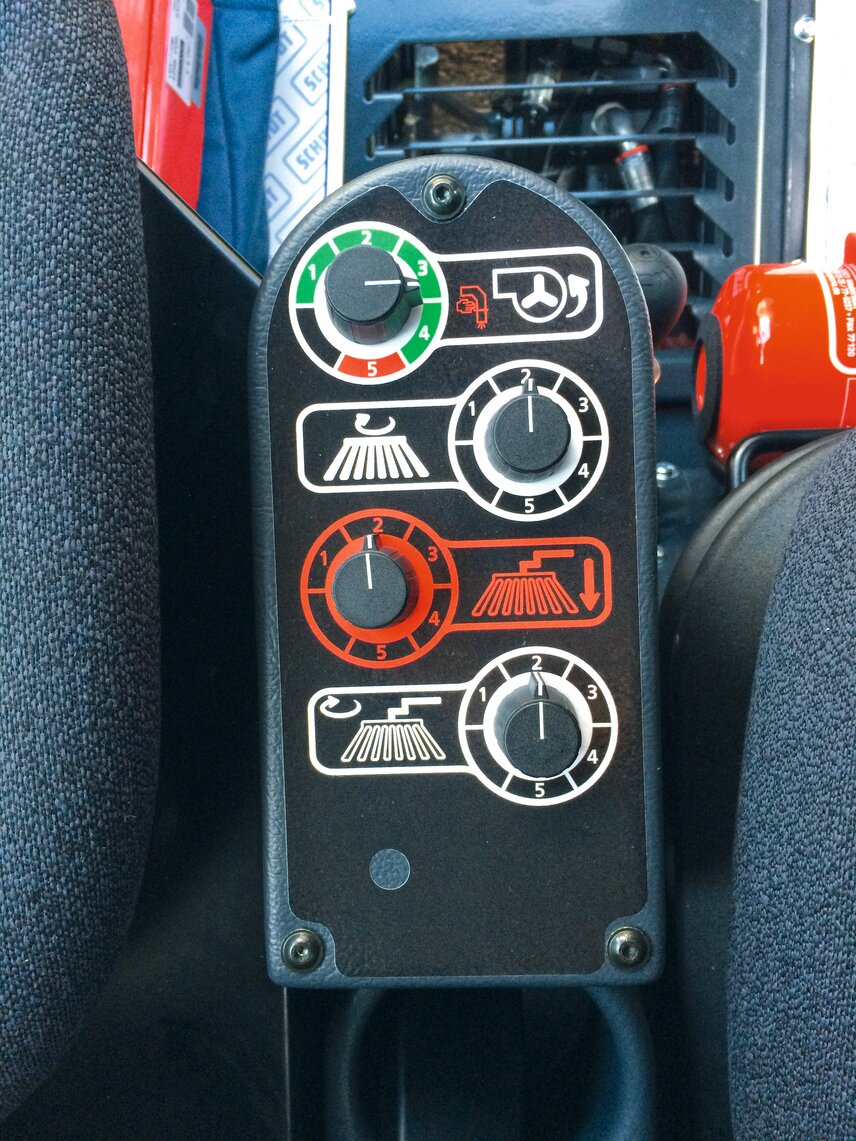

eSwingo 200+ finns med två oberoende sopsystem. Ett 2-borstsystem med en borstdiameter på 850 mm eller ett 3-borstsystem med en borstdiameter på 800 mm. Borstarna kan arbeta samtidigt eller individuellt och styrs genom praktiska reglage på förardörren. Borsthastigheten och trycket kan justeras steglöst. Borstarna kan kan utrustas med plast, stål eller blandade material, sugmunstycket kan utrustas med svängbara hjul, fast hjul eller medar.

2-borstsystemet med oberoende kontrollerbara borstar garanterar absolut rörlighet i varje sopande situation. Två stabila borstarmar med integrerade stötdämpare möjliggör sopningssbredder på upp till 2 900 mm. Oberoende borststyrning finns som tillval: separat styrbara borstar, upp/ner, vänster/höger, marktryckskontroll. Detta garanterar även rena sopresultat med minimalt slitage. Borsten återgår alltid till sin grundposition, även när vägförhållandena förändras. En version för tung ogräsanvändning finns också med hydrauliska lutningsfunktioner för borsten.

3-borstsystemet med fritt rörlig främre borstarm erbjuder ett brett utbud av alternativ och en sopningsbredd på upp till 2 600 mm. Vänster-höger inriktning av den främre borsten är lika möjligt som att sopa på två nivåer eller med tung ogräsborstsanvändning. Alla funktioner hos den främre borsten är hydrauliskt styrda, inklusive borstens stödtryck. Borstenheten under hytten säkerställer optimal matning av det sopade materialet till sugaxeln, en överlappning garanteras alltid. Som ett alternativ kan sidoborstarna också förlängas hydrauliskt och deras vinkel kan justeras. Detta säkerställer ännu bättre anpassning till markförhållandena i soparbetet.

Sug- och vattensystem

eSwingo 200+ är certifierad med den bästa nivån PM10 4-stjärniga och PM2.5. Certifikatet anses vara en kvalitetsfunktion i hela Europa och delar ut fyra stjärnor i PM10-testet för högsta nivå av luftföroreningskontroll samt bästa möjliga absorptionsprestanda med PM2.5.

För 2-borstsystemet finns det ett det utrustningsval av en sugmun med hydrauliskt manövrerad grov smutsflik eller en sugmun med höghastighet (HS-sugmun), som kombinerar fördelarna med en integrerad grov smutsflik med optimalt luftflöde. HS-sugmunnen garanterar maximal sugeffekt även vid låga hastigheter. Detta kan spara upp till 15% i driftskostnader.

Det finns en luftflödesoptimerad sugmun för 3-borstsystemet, vilket inte kräver en separat grov smutsflik. Grovt skräp kan enkelt samlas in genom att luta sugmunnen.

Koandas luftcirkulationssystem (Valfritt)

Med det unika Koandas luftcirkulationssystem och kombinationen med det trycksatta cirkulerande vattensystemet minskar utsläppen av skadligt fint damm med upp till 70%. En stor del av den dammluften sugs in i sugsystemet och återförs till sugmunen i en krets. Den lilla mängden kvarvarande luft rengörs med ett finporerat filter. Dessutom imponerar Koandas cirkulerande luftsystem med minskat buller, låg vattenförbrukning och tillåter sopning vid något under noll grader.

Det beprövade vattensystemet för tryckcirkulation returnerar stora mängder cirkulerande vatten till kretsen med hjälp av en avloppspump för återanvändning. Vattenåtervinningssystemet, med en skärmyta på 3,3 m2 i behållaren, sparar inte bara färskvatten utan utnyttjar också behållarens kapacitet optimalt. Genom att fylla vatten i behållaren (upp till 250 l) kan driftsområdet ökas med upp till 50%. Det uppsamlade sopmaterialet är både fuktat och komprimerat.

Den elektriska färskvattenpumpen levererar vatten till vattendysorna på de borstarna. Vattenkvantiteten för borstarna kan bekvämt styras från hytten.

- Unika Koandas luftcirkulationssystem

- Vattenåtervinningssystem, med en skärmyta på 3,3 m2

- Genom att fylla vatten i behållaren (upp till 250 l) kan driftsområdet ökas med upp till 50%

Sopbehållaren

Behållaren har en kapacitet på 2 m³ vilket möjliggör maximal sopkapacitet och större arbetsområden. Behållaren är tillverkad av korrosionsbeständig aluminium. En tippningshöjd på 1400 mm möjliggör tömning i alla vanliga smutsbehållare. Sugröret i behållaren finns även som tillval i slitstarkt rostfritt stål.

Ergonomi och komfort

Den rymliga hytten är utrustad med högkvalitativ ljud- och vibrationsisolering (72 dB (A)). Den främre vindrutan, som sträcker sig ner till golvet, och visningsfönstret i hyttens golv, ger optimal sikt över sopenheten och sugmunstycket.

Den utmärkta allsidiga sikten bidrar till en behaglig arbetsmiljö och stöder därmed säker drift i vägtrafiken. Det kraftfulla luftkonditioneringssystemet skapar ett behagligt och svalt arbetsklimat även vid höga utomhustemperaturer. Frisk luft sugs in och filtreras baktill på hytten. Hyttens luftfilter är utformat som ett pollenfilter.

Den viktigaste informationen syns med ett ögonkast på takkonsolens färgdisplay. Dessutom kan en mekaniker göra maskinspecifika inställningar på displayen. Med hjälp av det inbyggda diagnossystemet kan eventuella fel lokaliseras snabbt och effektivt.

Sopningsarbetet styrs via dörrens kontrollpanel med joysticks och tryckknappar. Med alternativet Auto-Drive kan alla sopande funktioner och körkommandon i sopningsläge bekvämt manövreras via den ergonomiskt formade multifunktionella styrspaken. Körning och sopning från en enda källa innebär också större säkerhet och mindre stress.

Smidig styrning med rattstång justerbar i höjd och lutning, farthållare, minimala pedalkrafter, ett förarsäte för hälsa med AGR-certifikat (”Aktion Gesunder Rücken”) samt manövrerings- och styrinstrument i ett optimalt greppområde som är självklara prestandaegenskaper hos en modern, ergonomisk arbetsplats.

Modern fordonsteknik

Varmförzinkningen av hela fordonsramen, sugmunstycket, viktiga stålkomponenter samt sopbehållaren ger ett högklassigt korrosionsskydd.

Det hydropneumatiskt upphängda chassit med hydrostatisk drivning och stora 15" hjul erbjuder högsta möjliga körkomfort i denna maskinklass. Hjulens höga lastkapacitet och stora kontaktytor säkerställer ökad säkerhet vid lågt marktryck, oavsett väg- och väderförhållanden. Som tillval kan den tillåtna totalvikten ökas till 5 000 kg.

Alternativt kan ett mekaniskt chassi väljas. Upphängningspaketet, som passar perfekt till maskinen, säkerställer säker och bekväm körning precis som en bil. Bra körkomfort, robusthet och frihet från underhåll kombineras optimalt.

Ett höj- och sänkbart chassie (tillval) förenklar körning i parkeringhus och och fastigheter med låga ingångar. Chassit kan sänkas med ca 70 mm med en knapptryckning. Systemet nivåanpassar sig själv automatiskt.

Den omkopplingsbara fyrhjulsstyrningen möjliggör extremt snäv vändradie. Rattningen på alla hjul övervakas med hjälp av styrvinkelsensorer, vilket möjliggör automatisk centrering - användarvänlig och säker. Ett hydrauliskt dubbelkretsbromssystem med skivbromsar på fram- och bakaxeln monteras som standard.

Brett utbud av alternativ

- Koanda luftcirkulationssystem

- Bakåtriktad kamera och kamera för sugmunstycke

- Ogräsborste inkl. hydrauliska lutningsfunktioner

- Handsugslang

- Högtryckstvätt

- Automatisk centralsmörjning

IntelliOPS telematikplattform

Om du vill övervaka, planera, styra i realtid, optimera eller till exempel fakturera tredje part för verksamheten på din eSwingo 200+, använd då de digitala lösningarna på vår IntelliOPS-plattform. IntelliOPS stöder dig i den effektiva användningen av din enskilda maskin såväl som i ett nätverk med flera maskiner, inklusive maskiner av andra märken. Här kan du läsa mer om våra digitala lösningar och hur du kan använda dem på ett sätt som är modulärt och anpassat till dina behov.

Kompletterande information

eSwingo kan hjälpa dig att minska koldioxidutsläppen och spara kostnader. Kontrollera själv genom att använda vår CO2-kalkylator och TCO-kalkylator.