Schmidt |Sopmaskin|Cleango 500

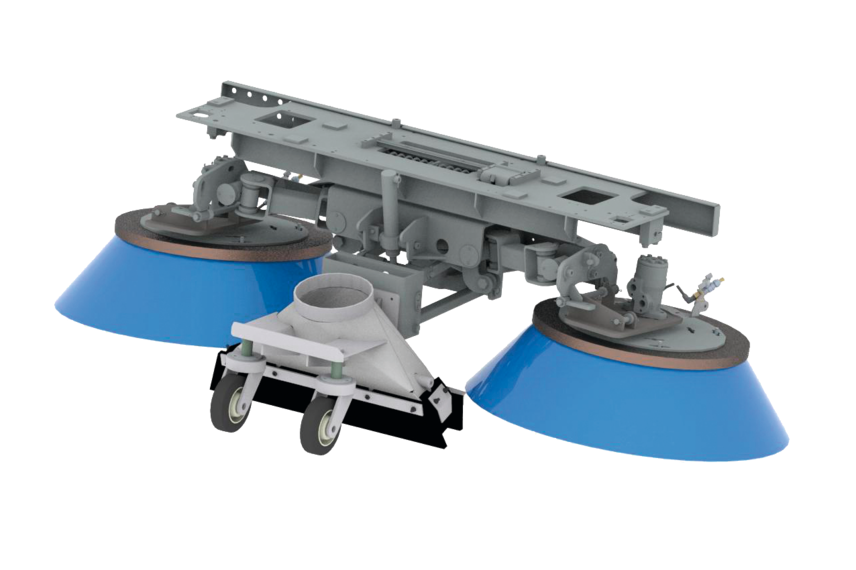

Sopteknik

Cleango 500 har ett borstsystem monterat framför framaxeln med en sopbredd på 2200 mm. Fördelen med konstruktionen är att kollisionsskador minimeras avsevärt och att och slitage på borsten minskas avsevärt.

Cleango 500 finns som två- eller treborstsystem. Med den valfria tredje borsten kan arbetsbredden ökas till 3550 mm. Detta möjliggör en större ytprestanda (upp till 64 000 m² / h), sopning på två nivåer och effektiv sopning i områden med mycket gatumöbler och snäva arbetsytor. Den robust designade armen med främre borsten kan användas både på vänster och höger sida av maskinen och är också lämplig för tungt ogräsarbete.

Alla funktioner på Cleango 500 kan styras hydrauliskt från manöverpanelen i förarhytten. Hela sopaggregatet kan flyttas hydrauliskt 300 mm åt höger och vänster. Med den oberoende borstkontrollen som tillval kan lutningen på de borstarna justeras hydrauliskt från hytten för att passa vägytans egenskaper. Borstarnas kontakttryck kan justeras separat till höger och vänster från hytten. Detta möjliggör bekväm och ren sopning av rätvinkliga hörn, rännsten och svåråtkomliga områden.

Sug och vattensystem

Sugmunnen är placerad bakom borstarna men framför framaxeln och bärs på rullar med konstant avstånd från marken. Sugmunnen och de borstarna utgör en enhet - borstarnas parallellogramupphängning garanterar optimal spårning och överlappar därmed sugmunnen. Den flödesoptimerade installationen av sugmunnen säkerställer att sopning kan utföras effektivt och med minskad bränsleförbrukning även vid låga fläkthastigheter. En hydrauliskt manövrerad grov smutsflik gör det möjligt att samla upp stora skräp. Fläktens hastighet kan enkelt och bekvämt justeras med flera variationer, vilket möjliggör snabb reaktion på förändrade förhållanden.

Färskvattensystemet har en volym på cirka 685 liter (med tillval upp till 1835 liter). Den kraftfulla vattenpumpen levererar två sprutmunstycken vardera på de borstarna och två munstycken i sugmunnen. Cleango 500 kan också utrustas med ett valfritt cirkulationsvattensystem. I det här fallet matas det cirkulerande vattnet från behållaren direkt in i sugmunnen, vilket sparar färskvatten och optimerar kapaciteten. Det uppsamlade avfallsmaterialet är både fuktat och komprimerat och endast ren luft med låg damm släpps ut i miljön.

Cleango 500 är certifierad med PM10 4-stjärniga och PM2.5 bästa nivå. Certifikatet betraktas i hela Europa som en kvalitetsfunktion och tilldelar fyra stjärnor i PM10-testet för högsta nivå av luftföroreningskontroll och bästa möjliga absorptionsprestanda med PM2.5.

Sopbehållaren

Sopbehållaren har en volym på 5 m³ vilket möjliggör maximal sopkapacitet och möjlighet till större arbetsområden mellan tömningar. Grundversionen är utrustad med tipputmatning. En hög dumpning med påtryckare för tömning av containrar finns också som tillval. En hydrauliskt låst baklucka med en stabil gummitätning tätar bakluckan för att hålla behållaren vattentät.

Behållarens ram är gjord av stål medan behållarens botten och sidor är fodrade med aluminium- eller rostfria stålplattor. Alternativt finns Cleango 500 med en ram helt i rostfritt stål.

Lövfiltret är fixerat över hela behållarens bredd och längd och gör att behållarens kapacitet kan utnyttjas till sin fulla potential. Den stora lövfilterytan förhindrar att den täpps igen och garanterar ett konstant luftflöde med 100% fyllning av behållaren. Filtret kan enkelt fällas ner för rengöring. Automatisk rengöring av lövfiltret för den främre delen finns som tillval.

Ergonomi och komfort

Vid utformningen av hytten var fokus på enkel användning och ergonomi med optimal sikt genom en vindruta som sträcker sig till hyttgolvet. Samtidigt ger ett fönster i hyttgolvet en tydlig bild av sugmunnen och borstarna. Två stora sidospeglar ger också en perfekt utsikt över arbetsområdet och omgivningen. Hytten är utrustad med högkvalitativt ljud- och vibrationsisolering. Med bara 66 dB (A) kan föraren koncentrera sig bättre och utföra uppgifter snabbt och säkert.

Alla kontroll- och manöverelement är ordnade runt den friska förarsätet med AGR-certifikat ("Kampanj för friska ryggar") och är inom räckhåll. Ett kraftfullt värme- och luftkonditioneringssystem säkerställer bästa möjliga inomhusklimat under arbetet. En smal och flera nivåer justerbar rattstång (i höjd och vinkel) är utrustad med alla trafik- och säkerhetsrelaterade funktioner och kontroller. Den ergonomiskt utformade övergången mellan gas- och bromspedaler, låga pedalkrafter och farthållare underlättar förarens arbete.

Sopenheten styrs via dörrpanelen med joysticks och tryckknappar. Den viktigaste informationen syns med en blick på färgdisplayen i takkonsolen, inklusive körhastighet, fyllnadsnivåer, temperaturer, motorvarvtal och arbetsförhållanden. Alternativet Auto-Drive är nytt. Alla sopfunktioner och körkommandon i sopläge kan enkelt manövreras med den ergonomiskt formade multifunktionella joysticken. En mekaniker kan göra maskinspecifika inställningar via skärmen. Det inbyggda diagnossystemet gör att eventuella fel kan lokaliseras snabbt och effektivt.

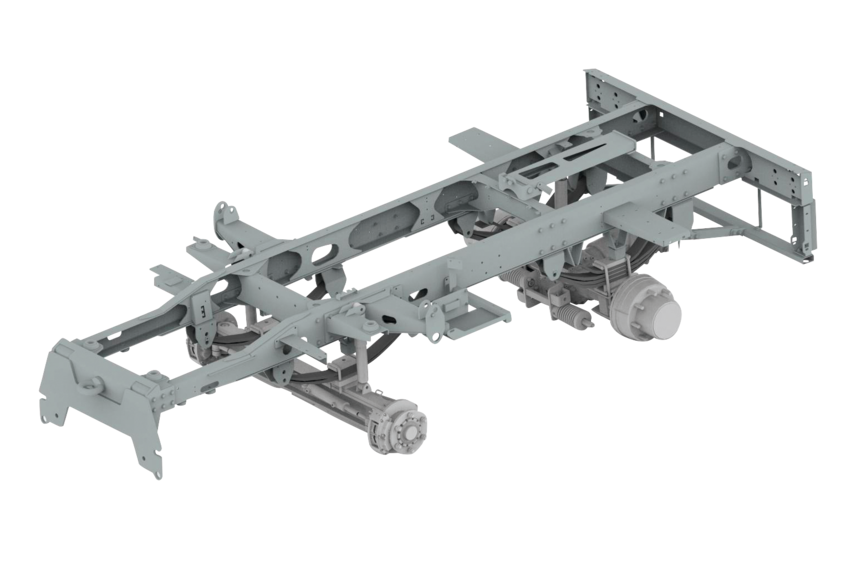

Modern fordonsteknik

Ramen på Cleango 500 är tillverkad av höghållfast stål och är grundad och målad i processer av hög kvalitet. Detta bildar ett effektivt korrosionsskydd och garanterar hållbar användning i alla väderförhållanden. Stigramkonstruktionen gör Cleango 500 lätt och samtidigt robust och pålitlig. C-profiler garanterar maximal stabilitet och vridstyvhet. Hydraultanken är också tillverkad av robust stål, medan sido- och bakvattentankarna är konstruerade av stabil, slagfast plast.

Fjädringspaketet med bladfjädrar och hydrauliska stötdämpare fram och bak, anpassade efter maskinen, säkerställer säker och bekväm körning. Stora 17,5" hjul med hög lastkapacitet säkerställer ökad säkerhet vid körning även vid dåliga väg- och väderförhållanden. Cleango 500 har den högsta nyttolasten i sin klass - upp till 6 600 kg tack vare robust fjädring, hög axellast och tvillingdäck på baksidan. En god svängradie på 68 °, i kombination med den korta hjulbasen på 1 850 mm, möjliggör optimal manövrerbarhet och en extremt snäv svängradie.

Det hydrauliska två-kretsade bromssystemet med skivbromsar fram och trumbromssystem bak, plus en valfri eller utrustningsberoende automatisk lastberoende bromsventil på bakaxeln, möjliggör enastående fordonskontroll.

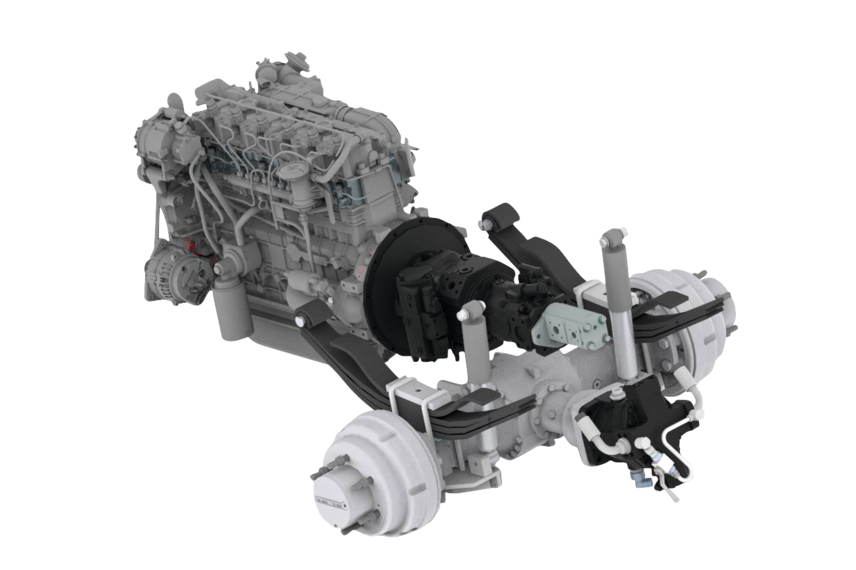

Körning

Cleango 500 är utrustad med en effektiv och kraftfull Euro 6c-dieselmotor som har ett av de mest avancerade avgasreningssystemen som finns på marknaden, inklusive dieseloxidationskatalysator, slutna partikelfiltersystem, ureainjektion (AdBlue) och SCR-katalysator. Valfria transporthastigheter är 25 /40 /45 /50 km / h.

Motorn, inklusive AdBlue-tanken, är perfekt integrerad i chassit så att Cleango 500 bibehåller optimal manövrerbarhet och flexibilitet. Den smidiga och kraftfulla 6-cylindriga motorn, i kombination med den nydesignade hydrostatiska drivenheten med Eco-Drive-funktion, garanterar bekväm och ekonomisk körning och kan spara upp till 20% i dieselbränsleförbrukning.

Genom att ändra drivsystemet kan Cleango 500 alternativt utrustas med en miljövänlig CNG-drift (Compressed Natural Gas).

Brett utbud av tillval

Främre tredjeborste

Ogräsborste

Bakåtriktad kamera och kamera vid sugmunnen

Högtryckstvätt

Takbom med HD-lans

Ytterligare vattentank

Handsugslang

Automatiskt centralsmörjning

Ljudisoleringspaket

LED-belysningspaket

Vinterunderhållsalternativ: Snöplog eller borste fram

IntelliOPS telematikplattform

Om du vill övervaka, planera, styra i realtid, optimera eller till exempel fakturera tredje part för verksamheten på din Cleango 500, använd då de digitala lösningarna på vår IntelliOPS-plattform. IntelliOPS stöder dig i den effektiva användningen av din enskilda maskin såväl som i ett nätverk med flera maskiner, inklusive maskiner av andra märken. Här kan du läsa mer om våra digitala lösningar och hur du kan använda dem på ett sätt som är modulärt och anpassat till dina behov.