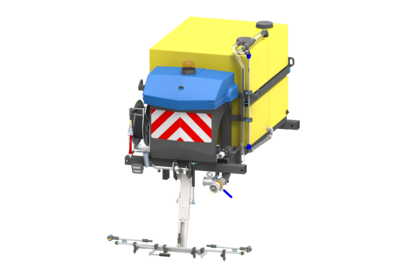

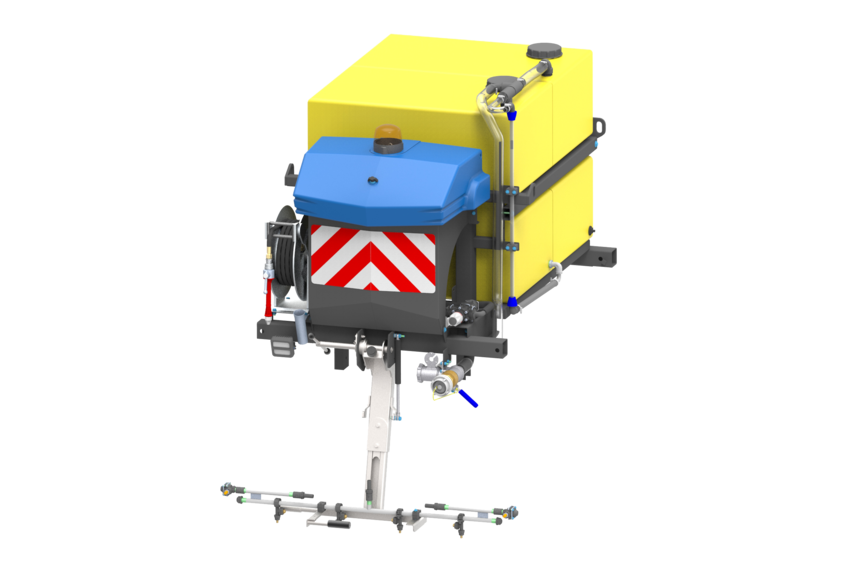

Schmidt|Sprayer|CSP

- Efficient de-icing in municipal and airport areas

- Even, lateral distribution, at low speeds too

- High manoeuvrability, thanks to its compact design

-

Very precise spraying through the super-effective ES control system

- Low life cycle costs due to the high-quality corrosion protection and low brine consumption.

- Designed for both preventive and curative de-icing applications.

- Suitable for towing vehicles such as small municipal vehicles and tractors, and for mounting on trucks with flatbeds, pickups and narrow track vehicles.

- Reduced environmental impact and higher economic efficiency.

Modular concept

The CSP's use of liquid de-icing agents is an alternative to potentially environmentally-harmful gritting agents. In dry or slightly humid conditions, and at temperatures down to -6°, this method is particularly suitable for municipal winter road clearance services when consumption of de-icing agents needs to be drastically reduced. When compared to pre-wetted spreading, the residual salt content on the carriageway is higher. Once applied, the very low dosage of the spraying fluid sticks firmly to the road surface and remains there, so that the frequency of use can be significantly reduced.

The modular design of the CSP enables individual configurations that are precisely matched to a variety of tasks and conditions. The modular liquid tanks are made of cold-resistant polyethylene and enable a number of customised configurations. The tank volume is precisely coordinated to the carrier vehicle’s axle loads. The CSP range can be easily mounted, disassembled or attached, so carrier and towing vehicles can be used all year round.

Possible variants:

- Variant with flatbed with 700, 1000, 1600, 2400 or 3000 l

- Variant with trailer with 1000

- Variant with three-point-linkage (Cat II/IIIN) with 350, 650 or 1000 l

Dosage and distribution system

For efficient de-icing, the exact dosage of the spray agent is vital. For this reason, the dosing is carried out in a closed electric-hydraulic circuit. The spray quantity is adapted to the driving speed via the speedometer reading and, depending on the distance travelled, good distribution is achieved, even at minimum dosage. The uniform application of the spray liquid is achieved via a spray bar mounted on the rear of the sprayer. Depending on the desired dosage and driving speed, the CSP can be equipped with either a single or double row of sprayers. Air injector nozzles are used to apply the spray agent, which produce large drops of liquid, optimising their impact. The spray nozzles are located close to the road surface, ensuring an even spray pattern.

A diaphragm pump ensures the spray liquid is efficiently moved from the tanks to the distribution system. Three spraying sections on the spray bar allow flexible adjustment of the required spraying width, while the proven nozzle technology ensures even application of the de-icer to the road surface. The nozzles are arranged side by side, creating an overlapping spraying result and more effective de-icing.

Drive options

As standard, the CSP is driven by the vehicle hydraulics of the carrier vehicles, and important control and hydraulic components are conveniently and centrally located in one area.

Control and information systems

The highly effective EvolutionLine control system ensures that the correct amount of spraying material is always applied for the selected dose. The spray quantity is road speed-related and adjusted automatically to suit the driving speed based on the speedometer reading.