These upgrades translate into faster lead times, higher-quality products, greater consistency, and the capacity to take on larger, more complex projects. By enhancing precision, efficiency, and overall workflow, we’re ensuring customers get the reliable, high-performing equipment they need—exactly when they need it.

Why Upgrade?

The goal of these upgrades was simple: improve the customer experience. By increasing manufacturing capacity and refining our production processes, Monroe can produce higher-quality products more quickly, helping customers meet their operational deadlines while maintaining strict standards for performance and reliability.

Equipment Highlights and Customer Benefits

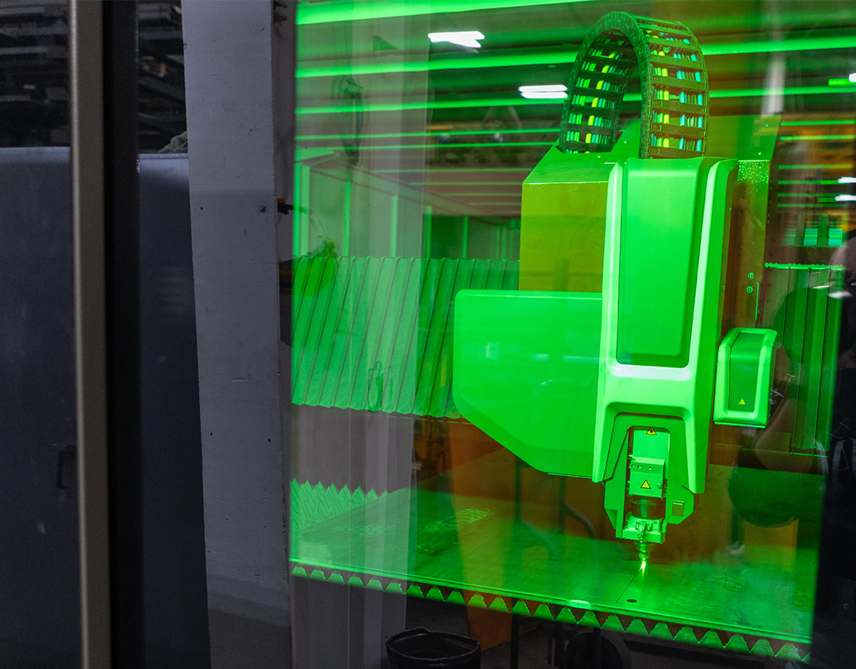

Fiber Laser

The new fiber laser delivers faster, more precise cutting. For customers, this means shorter lead times, tighter tolerances, and parts that fit perfectly the first time.

Press Brakes

With two upgraded press brakes and one new addition, we can bend and form materials with greater flexibility and accuracy. Customers benefit from consistent product quality and the ability to handle a wider variety of part specifications.

Plasma System

The upgraded plasma system produces cleaner, faster cuts, which translates to better-quality parts and more reliable delivery schedules for our customers.

3D Tube Laser

This addition enhances our tube cutting capabilities, allowing us to tackle complex shapes with higher precision. Customers can expect improved product quality and expanded project possibilities.

Sheet Roller & Robot

Enhanced sheet rolling equipment and robotic welders increase capacity while reducing manual errors. The result? More consistent products, faster turnaround, and safer production processes.

Process Improvements

These upgrades have streamlined workflows, automated repetitive tasks, and improved collaboration between operators and technology. Customers see the impact in every order: faster production, reduced errors, optimized material use, and on-time delivery—even for high-volume or complicated projects.

Impact on Operators & Team

Our team is more efficient, skilled, and engaged thanks to these upgrades. Happier, more capable operators lead to fewer errors, more consistent quality, and a smoother production process—directly benefiting customers with products they can rely on.

Customer Impact

Ultimately, these upgrades allow Monroe to deliver more than just equipment—they deliver peace of mind. Customers experience:

- Faster lead times and quicker turnaround on orders

- Higher quality and more consistent product performance

- Expanded capabilities to support larger, more complex projects

- Greater confidence in Monroe as a reliable, innovative partner

Looking Ahead

Monroe is committed to continuous innovation, always looking for ways to enhance capacity, precision, and efficiency. Future technology investments will continue to focus on delivering measurable benefits for our customers, ensuring we remain a leader in the municipal equipment market.

“Our investment in advanced equipment and improved processes is all about elevating the customer experience—delivering faster, more accurate, and more reliable products. These upgrades have a direct impact on every customer we serve.” — Chris Barber, Director of Manufacturing Monroe