Harsh conditions, smart solutions

Temperatures as low as –25 °C, frequent heavy snowfall, strong winds and icy runways – this is everyday reality at a Greenlandic airport. Compared with airports in Central Europe, operations are far more frequent and often need to happen at short notice, as weather changes can occur extremely quickly. For the teams, this means short response times, efficient processes and equipment that must be ready for use at any moment.

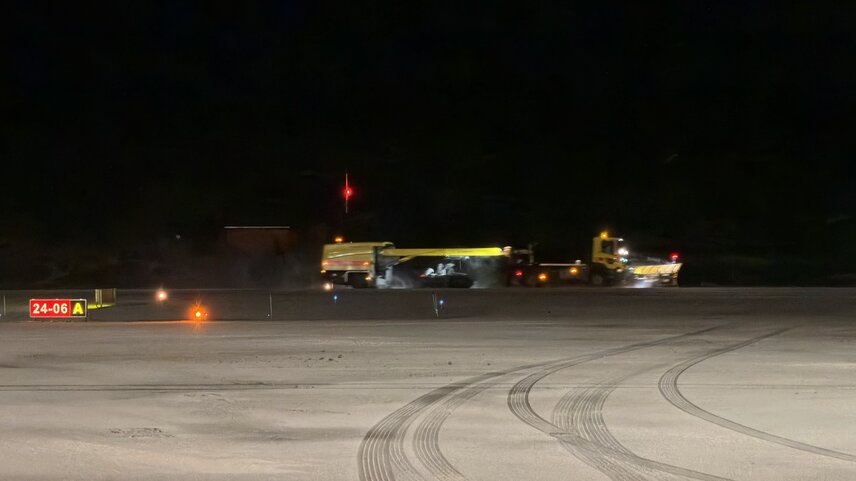

To meet these demands, Greenland Airports has relied on winter service technology from Aebi Schmidt for many years. Recently, three more Schmidt TJS 630, one Schmidt ASP24 and one Schmidt AS 660 were delivered to Ilulissat. This ensures that, when the international airport opens, a complete fleet of machinery is available that is designed for heavy snowfall and fast clearing cycles.

But it is not enough to simply provide the machines: they must be adapted to local conditions. Our service technicians were on site during delivery and worked together with the staff to train operation, maintenance and deployment under severe weather conditions. This includes working with limited visibility, strong crosswinds and icy taxiways. Only when processes and technology work seamlessly together can aircraft take off and land safely, even in Arctic conditions.

Proven reliability in the north

Schmidt airport equipment has long been a trusted partner for winter service in Greenland. More than twenty machines are already in operation today – proof of their reliability under extreme conditions. What matters is not only the robust technology but also the close cooperation with the operators: maintenance, service and training are regularly coordinated on site to ensure that winter operations run smoothly at all times.